Why Industry Edge Controllers?

With the development of smart manufacturing and the Industrial Internet of Things, edge computing and cloud storage of on-site data have become necessary requirements for many modern factories. Traditional PLCs, which are mainly used for small-scale control of on-site devices, can‘t meet the needs. Factories need controllers with stronger communication capabilities, big data processing capabilities, multitasking and collaboration capabilities, and the ability to connect to the cloud for remote processing and real-time control.

At the same time, with the expansion of production scale, new demands for cross-equipment, cross-factory, and even cross-country communication, and data analysis are getting more and more important for the factories.This also poses higher challenges to PLC capabilities: the vertical coordination of the entire production line and the entire factory area, and the horizontal coordination of industrial control software, SCADA system. Therefore, Industrial Control + Internet + Intelligence has become a new trend in PLC development.

Seeed Studio, as the design partner of Raspberry Pi, has been investing a lot into developing Raspberry Pi industry devices to satisfy diversified Industrial Internet of Things (IoT/IIoT) needs, and has recently launched the Edge Series to meet the different needs from users.

What is the Edge Series?

The Edge Series is a lightweight industrial edge controller series launched by Seeed Studio. It is defined as an OT-IT Bridge in industrial automation scenarios, integrating PLC/PAC, IPC, IIOT gateway, OPC UA Server and even HMI (Edgelogix-RPi-1000) , functioned as one. The Edgelogix-RPi-1000 and EdgeBox-RPi 200 are powered by Raspberry Pi Compute Module 4 (CM4), EdgeBox-ESP-100 is powered by ESP.

From compact industrial edge controllers to modular version, from no HMI to built-in HMI or with HMI possibilities, from Raspberry Pi powered to ESP powered and so on. Each product from the Edge Series has its own applicable scenarios and advantages.

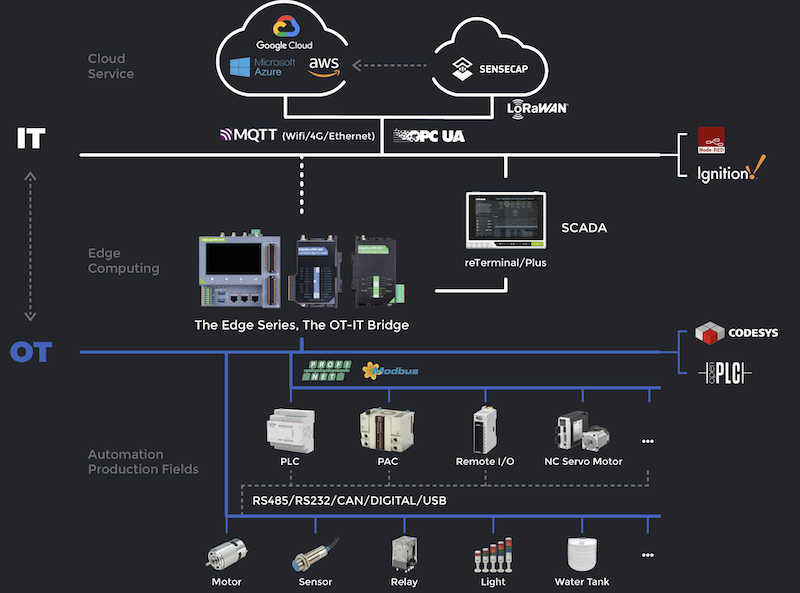

The Edge Series build the OT (Operational Technology) and IT (Information Technology) communication bridge between traditional controllers, actuators, and the cloud services. It plays as the SCADA system together with reTerminal/Plus as the Panel PC, providing the affordable, available and also reliable industry automation solution.

How does Edge Series Work?

The Edge Series, designed and manufactured in compliance with industrial standards, makes the seamless connection between OT and IT with multiple industrial fieldbus or protocol, such as RS485/232, CANBUS, Profinet, Modbus, and network transmission like Ethernet, 4G, LTE, LoRa, WiFi and Bluthtooth.

The Edge Series receives field data (sensors, control IO, etc.) and excuting multi-threaded data local calculation. This greatly protects data security, improves data processing accuracy and real-time performance. It constitutes the SCADA system together with the reTerminal/Plus, which functions as the Panel PC. And then the data could be transmitted to the Cloud for storage and remote management and control relying on its software and wireless capability. The whole system (The Edge Series + reTerminal/Plus) serves as the OT-IT bridge in the middle “Edge Computing” layer, connecting the Automation Production Fields and the Cloud service. Here Seeed Studio provides you with the private cloud possiblity thanks to SenseCAP.

With the architecture above, it realizes the closed-loop control of the whole process from “Connection-Collection-Analysis-Decision-Connection” for an automated factory, and finally improves the overall productivity for the factory.

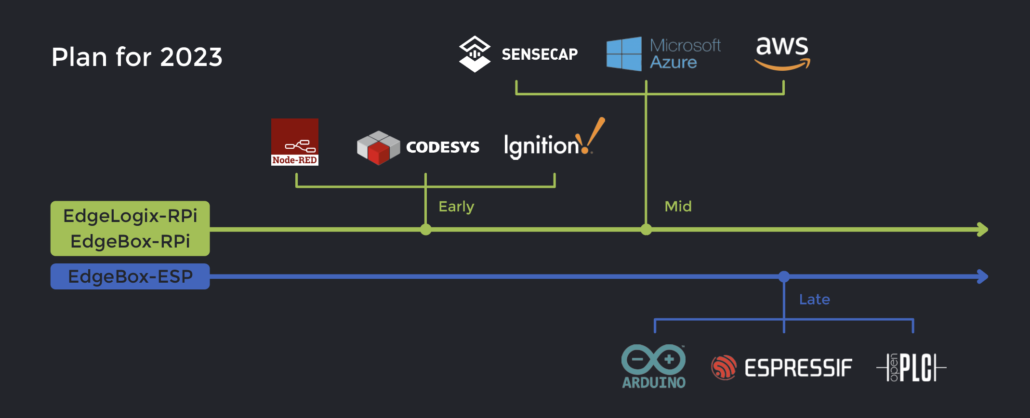

Software Roadmap

Of course, a hardware device without software is soulless. Seeed Studio, as an IIoT solution provider, will of course do the best to provide customers with a complete solution combined with software and hardware. We are adapting the software step by step according to the plan in the roadmap.

A complete tutorial will be provided to customers to help them get started using Edge Series more easily and quickly. Also benefiting from the open source software ecosystem of the Raspberry Pi, the cost of using and learning the Edge Series is lower. More people, more engineers, and more factories can use the Edge Series to achieve the industrial automation they need faster.

I really like this article. It addresses my exact needs. I ordered the RPI-1000 about 1 month ago. I am hoping to be able to run codesys and ignition edge on it. Will that be possible? If so could you please send instructions on how to do so ? Will it have a standard operating system that I can run ignition edge on? Jenna I sent you a meeting request for next week did you get it? I have not heard back from you?

Thank you, Roger. Our engineers are working hard to provide helpful guidance and instructions to you and other customers. We will keep our users informed of updates to our documentation and guidance in the near future. Regarding the meeting request you sent, I have replied to you in the email. Happy new year in advance!