Pharmaceutical Production with AI-Powered Process Monitoring

Hardware: reServer Industrial J4012, powered by NVIDIA Jetson Orin NX 16GB

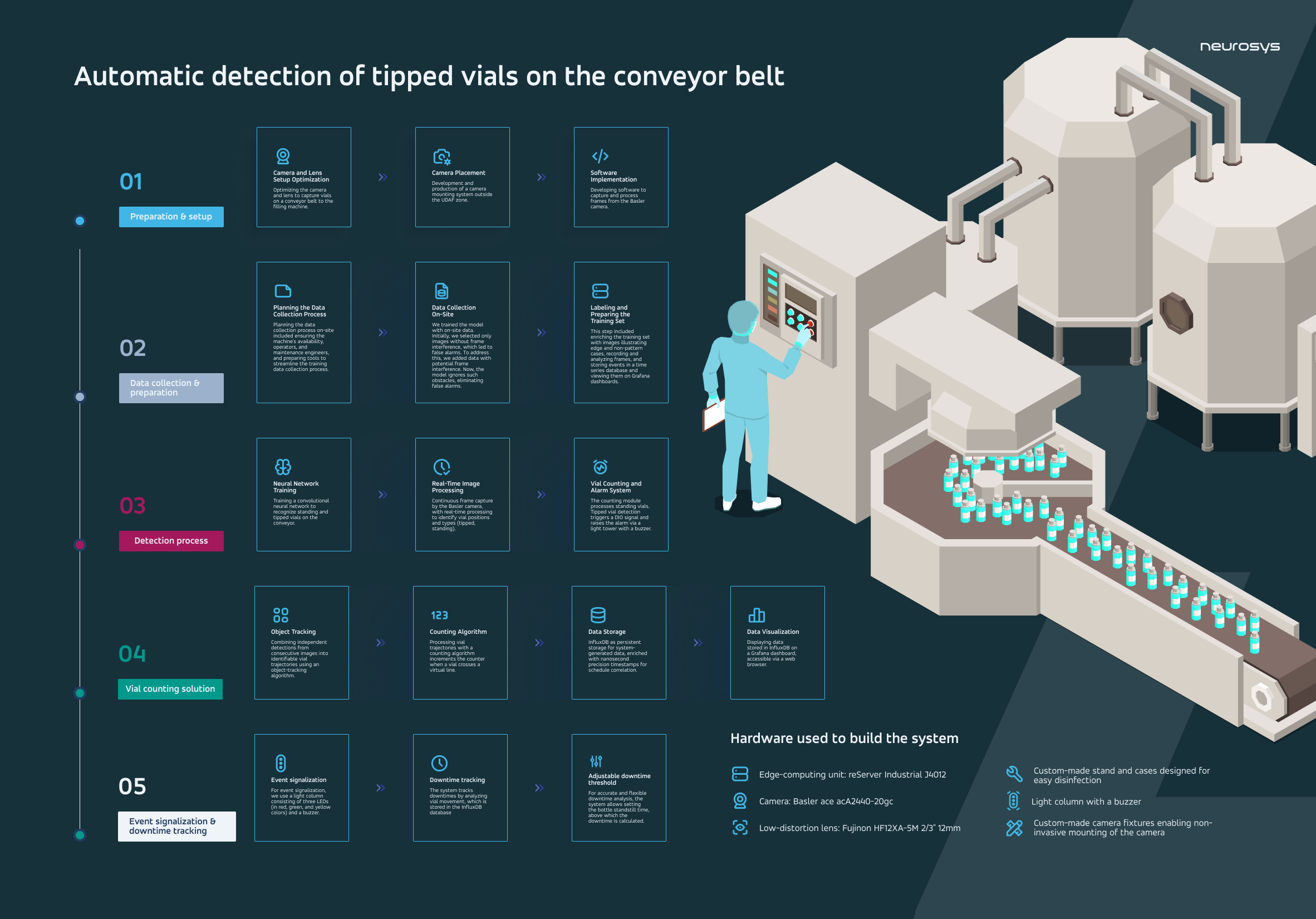

Use Case Provider: NeuroSYS

Application: Abnormal Detection in Production Line

Industrial: Pharmaceutical

Deployment Location: Norway

A global pharmaceutical company sought to enhance the efficiency and accuracy of its production process by integrating advanced AI technologies. Their challenge was to detect anomalies, such as tipped vials on conveyor belts, without disrupting existing workflows or requiring extensive reconfiguration of equipment. That’s how the whole solution got started, combining Seeed reServer Industrial J4012 edge device with NeuroSYS AI software platform together to deliver an innovative solution, transforming their production monitoring with an AI-enabled camera system.

Background

Pharmaceutical production lines often handle vials of varying materials (plastic and glass) and capacities (7 to 100 ml), totaling seven distinct types. Traditionally, the process relied on manual tuning of sensors and equipment reconfiguration for each vial type. These limitations resulted in inefficiencies and downtime, especially when tipped vials reached the filling machine.

The company required a versatile solution to address this challenge—one capable of real-time anomaly detection and performance monitoring while minimizing physical intervention.

Initial Challenge

The key challenges included:

- Detecting tipped vials on a moving conveyor belt.

- Minimizing false alarms caused by obstructions or unanticipated scenarios.

- Ensuring the system can adapt to various vial types without retooling machinery.

- Developing a scalable, non-intrusive solution that could integrate seamlessly with existing workflows.

Solution

The whole system implemented an advanced vision AI pipeline leveraging a combination of industrial hardware and AI-driven software.

Components

- Hardware: An industrial-grade camera integrated with the reServer industrial J4012 edge computing unit, powered by NVIDIA Jetson Orin NX 16GB.

- Software: Machine learning models trained on production data to detect anomalies and gather insights.

- Dashboard: Custom visualizations for real-time monitoring and historical analysis.

Implementation Process

- Optimized Setup:

- The camera and lens were calibrated to capture high-quality images of vials as they moved along the conveyor belt.

- During the Proof of Concept (PoC) stage, the system operated behind a plastic curtain to validate functionality without disrupting production.

- Real-Time Analysis:

- Frames captured by the camera were processed on the reServer Jetson device in real-time using convolutional neural networks (CNNs).

- The system determined vial positions (standing or tipped) and triggered alerts for anomalies.

- Data Processing and Visualization:

- Data was stored in a local database and visualized on dashboards, providing insights into machine performance.

- A vial counting module tracked both standing and tipped vials for statistical analysis.

- Enhanced Alert Mechanisms:

- Detection of a tipped vial activated a signal tower with visual (light) and auditory (buzzer) alerts.

Challenges Encountered During Implementation

During implementation, the system faced challenges to meet the specific deployment scenarios. for example, there could be some false alarms happening which are caused by operator hands entering the camera’s field of view, it’s finally optimized by retraining the machine learning model with additional obstructed images which includes obstructions. Sometimes the vials getting stuck or tipped at curved conveyor segments could be misclassified, and the dataset gaps that overlooked scenarios involving occlusions and bends. These issues were all addressed by enriching the dataset to improve robustness, ensuring accurate performance in diverse conditions.

Results and Achievements

The system delivered remarkable results, transforming the client’s production process:

- Anomaly Detection: Achieved 99.89% accuracy in detecting tipped vials, regardless of material or capacity.

- Downtime Monitoring: Enabled precise downtime tracking, counting delays after 10 seconds of no vial movement.

- Statistical Insights:

- Counted tipped vials for quality monitoring and standing vials to assess machine efficiency.

- Provided metrics for machine cycle optimization.

- Scalability:

- The same hardware setup was enhanced with new functionalities, requiring only software updates.

- Features like snapshot saving of anomalies allowed for deeper analysis of system performance and false positives.

Additional Benefits

- Flexibility: Eliminated the need for retooling and physical modifications by enabling remote software updates.

- Future-Proofing: New scenarios and events can be incorporated into the model as they occur, ensuring continuous improvement.

- Scalable Solution: With minimal hardware adjustments, the system can evolve to handle additional tasks or integrate with advanced analytics platforms.

This project showcases the transformative potential of AI in industrial automation, setting the stage for smarter and more efficient manufacturing processes. The reServer Jetson edge device not only addressed the pharmaceutical company’s immediate challenges but also provided a robust platform for continuous innovation. By leveraging the Jetson edge vision AI technology, the client gained real-time anomaly detection, improved machine efficiency, and actionable insights into their production process—all while reducing manual intervention and hardware dependency.

By implementing this solution, the client not only resolved their immediate challenges but also gained a robust and scalable system for ongoing innovation and operational excellence.

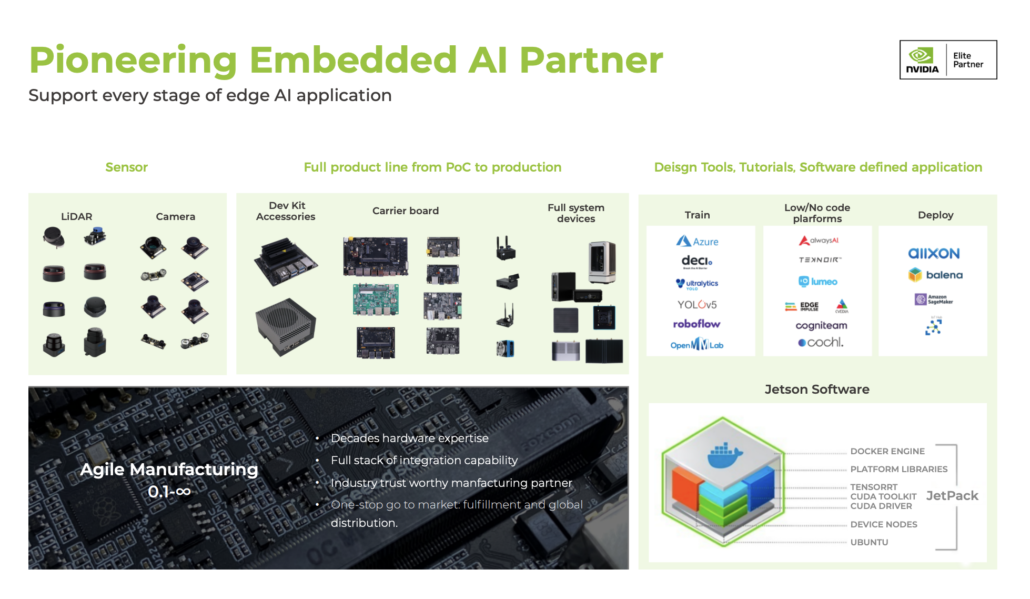

Seeed NVIDIA Jetson Ecosystem

Seeed is an Elite partner for edge AI in the NVIDIA Partner Network. Explore more carrier boards, full system devices, customization services, use cases, and developer tools on Seeed’s NVIDIA Jetson ecosystem page.

Join the forefront of AI innovation with us! Harness the power of cutting-edge hardware and technology to revolutionize the deployment of machine learning in the real world across industries. Be a part of our mission to provide developers and enterprises with the best ML solutions available. Check out our successful case study catalog to discover more edge AI possibilities!

Discover infinite computer vision application possibilities through our vision AI resource hub!

Take the first step and send us an email at edgeai@seeed.cc to become a part of this exciting journey!

Download our latest Jetson Catalog to find one option that suits you well. If you can’t find the off-the-shelf Jetson hardware solution for your needs, please check out our customization services, and submit a new product inquiry to us at odm@seeed.cc for evaluation.