PCB DFM vs PCBA DFA: What’s the difference?

The PCB industry is no stranger to odd terms and the proliferation of Chinese manufacturers setting up their own shops on the global stage is somewhat partly to blame for that – Ever heard of a processing side, EQ or mark point?

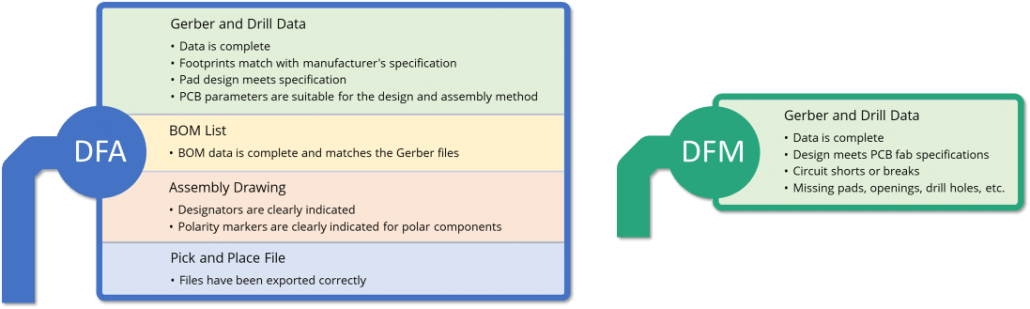

In most recent times, the terms DFM (Design for manufacture), DFA (Design for assembly) and, more widely, DFX (Design for Excellence) have appeared in many an electronics hobbyists and novice’s vocabulary. To clear up the confusion, we’re trying to make the term PCBA Design for Assembly (PCBA DFA) stick to highlight the distinction and importance of this step in a turnkey environment. PCB Design for manufacturing (PCB DFM) is steadily becoming a household name and often fab houses will say they offer free DFM review. But compared to a PCBA DFA – the level of verification and scope is miles apart.

Here we highlight the differences between the typical PCB DFM and PCBA DFA, and give reasons why you should be investing in good DFA practices and checks.

Strictly speaking, Design for Manufacture pertains to the stages that go into making the parts of a device – for electronic assembly, that would mean the individual components and the PCB. Therefore, it makes sense that Design for Assembly, pertains to the stage where all these parts are put together, i.e., populating the PCB. But in some circles, the assembly of a complete product, like a box-build with screws, casing and packaging is more like assembly. There is even DFMA term floating around to refer to both manufacture and assembly due to significant overlap. Such nuances can cause a bit of confusion when it comes to definitions and names.

For the big boys, strict and distinct methodologies exist for the traditional DFM and DFA disciplines that notably have specific focuses on yield and cost. But with the flourishing custom PCB industry, the world of manufacturing has become more and more accessible to more and more of us. And as a result, the terms DFM and DFA has evolved into something quite different.

In the most basic sense, you could say that DFM ensures that a product is manufacturable, i.e., That a printed circuit board can be manufactured (the alternative name ‘Design for manufacturability’ seems to lean towards this too). It, therefore, follows that DFA would ensure that something can be assembled. But notice that there is no specific focus on cost or yield with the ‘take my money and make it happen’ approach that has somewhat plagued the custom manufacturing industry.

To really nail it in:

PCB DFM is required from the onset.

PCBA DFA is something you wished you had done or done more carefully from the onset.

PCB DFM is an absolute must for manufacturers – you are not a good manufacturer if you can’t even say if you can manufacture something.

If something cannot be assembled because of problems with the supplied materials – that’s not really the assemblers’ fault. If you give a chef the ingredients for a pizza and ask them to make a cake, they are not going to be very impressed.

Similarly, for turnkey PCB assembly, and product development in general, we are essentially gathering the ingredients for that spongey red velvet – but every so often, we receive pepperoni and tomato puree instead.

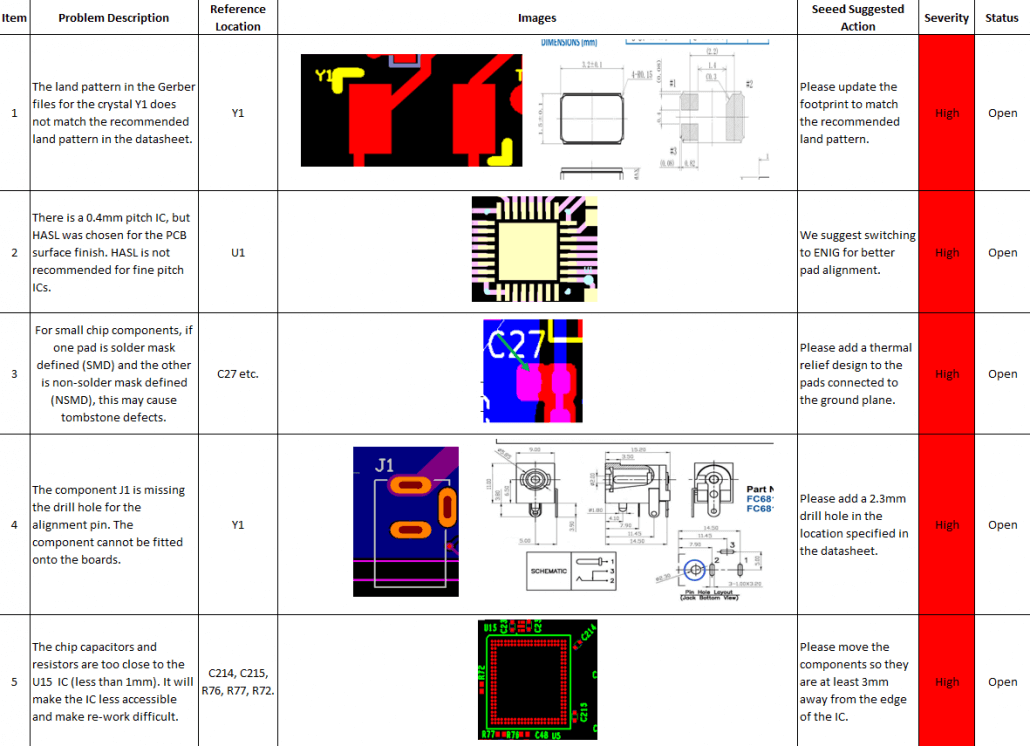

As every PCB designer knows, one small mistake could ruin your boards and the possibility of pulling off a meaningful run. Getting everything perfect first-time round is what everyone wants but in reality, with so many different parts, from different manufacturers, with varying degrees of reliability coming sit on your one PCB board – it rarely happens. It’s easy to forget the complexity and margin for error involved in making a single working device that something as essential as a footprint check is often overlooked or not done properly. A DFA check done by a qualified practicing engineer can be just the thing required.

Seeed Fusion offers Design for Assembly review for all PCB assembly orders to remove nasty surprises when most necessary. Performed by our own experienced engineers with ample hands-on product development experience, there’s no one better to give you peace of mind. While optional, choosing to have the review done or not can make or break your project.

Now, Seeed Fusion is including the highly acclaimed Design for Assembly (DFA) review with every PCBA order – 100% free. No prices have been hiked up or additional fees squeezed in anywhere, go ahead, check! We simply cannot understate the value of this service, and we recommend it so much that we are throwing it in completely free from now on.