Summary

Concrete structures typically show signs of deterioration after 40 to 50 years, emphasizing the importance of regular inspection and repairs to prevent accidents and safeguard infrastructure. Detection of cracks is a key diagnostic criterion for concrete structure degradation. While visual inspection is commonly used, it has drawbacks such as being time-consuming and prone to missing small cracks in large structures. Furthermore, the correlation between crack growth and temperature variations suggests that visual inspections may overlook cracks during contraction periods. This underscores the need for more efficient and comprehensive inspection methods to ensure the longevity and safety of concrete structures.

Naveen Kumar, an innovative engineer from Japan, deployed Edge Impulse on our Raspberry Pi-powered HMI reTerminal and trained a model. Using a machine vision system, the model detects and locates surface cracks in concrete structures, enabling predictive maintenance.

Key Info

Seeed’s solution: Raspberry Pi-powered HMI reTerminal

Industry: Surface Crack Detection and Localization

Challenge

Traditionally, specialists inspect structures by visually identifying cracks, documenting their observations through sketches, and subsequently compiling inspection data. However, this method is not only time-consuming and expensive but also lacks precision in crack detection. The implementation of a compact and portable hardware device, featuring a suitable display, offers a transformative solution. Such a device facilitates the real-time presentation of crack data analysis results. Furthermore, the content generated on this computing module can be effortlessly duplicated or transferred to other edge devices, enhancing efficiency and enabling seamless data sharing across various inspection points. This highlights the crucial role of edge devices in streamlining and improving the crack detection process in structural inspections.

Solution

Choosing an open-source and open platform is crucial for the ease of algorithm deployment, subsequent batch deployment, and portability. Therefore, the Raspberry Pi platform became Naveen’s top choice. Seeed has been deeply involved in the Raspberry Pi field for many years and offers highly mature and reliable Raspberry Pi hardware products and solutions. As a long-term user of Seeed, Naveen did not hesitate to select Seeed’s reTerminal. It perfectly meets his requirements with its compact and portable size, high-quality screen display, and expandability. The Raspberry Pi CM4 solution ensures its reliability and performance.

Naveen built a surface crack detection application using machine learning. A pre-trained image classification model is fine-tuned using the Transfer Learning with the Edge Impulse Studio and deployed to the Seeed reTerminal (based on Raspberry Pi Compute Module 4) which detects surface cracks in real-time and also localizes them.

Know more details about this project, please click here to get more.

Seeed Studio's Raspberry Pi Ecosystem

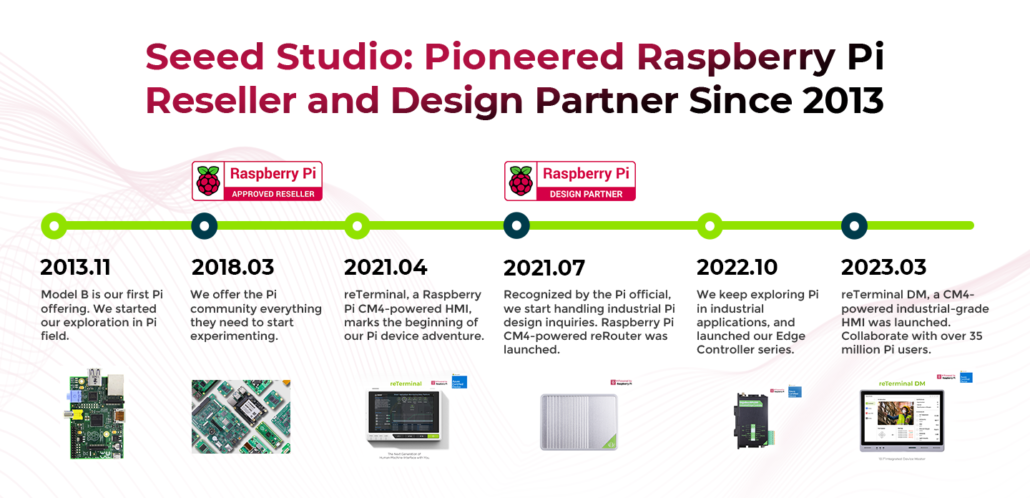

Seeed Studio has been serving the Raspberry Pi user community since 2013 and took the lead to join the approved reseller and design partner. Since the first version of reTerminal in 2021, we have a series of products including reRouter, edge controller series, and this year reTerminal DM, serving creators, makers, enthusiasts, students, engineers, enterprises as well as industries, and every scenario needing Raspberry Pi.

More Resources

- Explore more products, full system devices, customization services, and use cases on the Seeed Raspberry Pi page.

- Download our latest Raspberry Pi success case booklet to know how Seeed and Seeed’s Raspberry Pi-powered products and solutions assist in tackling real-world challenges. Share your idea and story with our team at edge@seeed.cc.

- Dive deep into our Raspberry Pi wiki page to get yours started.

- Download our latest product catalog to find the ones that suit your needs.

- Wants to discuss more customization possibilities, please check out our customization services, and submit your inquiry to edge@seeed.cc to have a deeper discussion and evaluation for you.