To address the challenges of inefficient practices, animal health, and consumer demands for transparency in poultry farming industries, our partner DunavNET collaborated with Axceta and deployed the poultryNET, an IoT/AI-based solution powered by Seeed Studio SenseCAP LoRaWAN devices in the Montreal area in the poultry barns of Sollio Agriculture to revolutionize the poultry farming industry. The poultryNET combines edge and cloud functionalities, utilizing SenseCAP LoRaWAN sensors and video cameras to monitor environmental conditions, chicken behavior, and operational parameters, which improves animal welfare, and production efficiency, and establishes a traceable food supply chain. The project reduced mortality rates and improved feed conversion ratios, and it also empowers farmers with real-time guidance and decision support to optimise their poultry production, which offers a promising approach to enhance efficiency and profitability in poultry farming.

- Solution: Poultry farm decision support and management

- Participating Partners: DunavNET, Axceta, Sollio Agriculture

- Seeed Products used: SenseCAP LoRaWAN Outdoor Gateway- EU915, SenseCAP S2103 CO2, Temperature, and Humidity Sensor, SenseCAP S2102 Light Intensity Sensor, NVIDIA® Jetson AGX Orin

- Industry: Smart Agriculture

- Solution Deployed in: Montreal area, Canada

In Canada, chickens dominate the farming industry as the most widely raised animals. The estimated population of chickens raised for meat reaches a staggering 107.9 million. These chickens, known as broiler chickens, are specifically bred for their meat production. Remarkably, Canada boasts over 7,000 broiler chicken farms spread across the country and most of them are managed in a traditional way (source: BCSPCA).

Challenges

The traditional poultry farming industry faces significant hurdles in achieving optimal management, coordination, and data utilisation. Inefficient practices not only decrease productivity but also compromise animal health and welfare. Ensuring continuous tracking of a multitude of operational parameters, from environmental conditions and the growth progress to monitoring chicken behaviour to detect potential issues in early stages, is difficult and is becoming even more difficult with the reduced number of experienced farm workers. All these parameters can have a significant impact on the quality of poultry production and may be the source of huge losses for farmers.

At the same time, consumers are becoming very conscious about the food they are eating, continuously asking for more not only in terms of quality, but also in terms of knowing where the food comes from, while demanding compliance with all relevant animal wellbeing regulations. Being able to document the key parameters of interest to consumers in a trustworthy and transparent manner is becoming an important aspect of the farm to fork supply chain.

These challenges pose a substantial obstacle to meeting the increasing global demand for food driven by a growing population in a sustainable manner.

Solution

To overcome these challenges, DunavNET developed poultryNET, an integrated farm management and decision support solution, which has been deployed in the Montreal area in the poultry barns of Sollio Agriculture with the partnership of Axceta. By harnessing the power of IoT and ML/AI technologies, poultryNET combines edge and cloud functionalities with embedded domain knowledge to provide a range of features empowering farmers, from enabling them to continuously monitor and record parameters of interest, to alerting them when actions are to be taken.

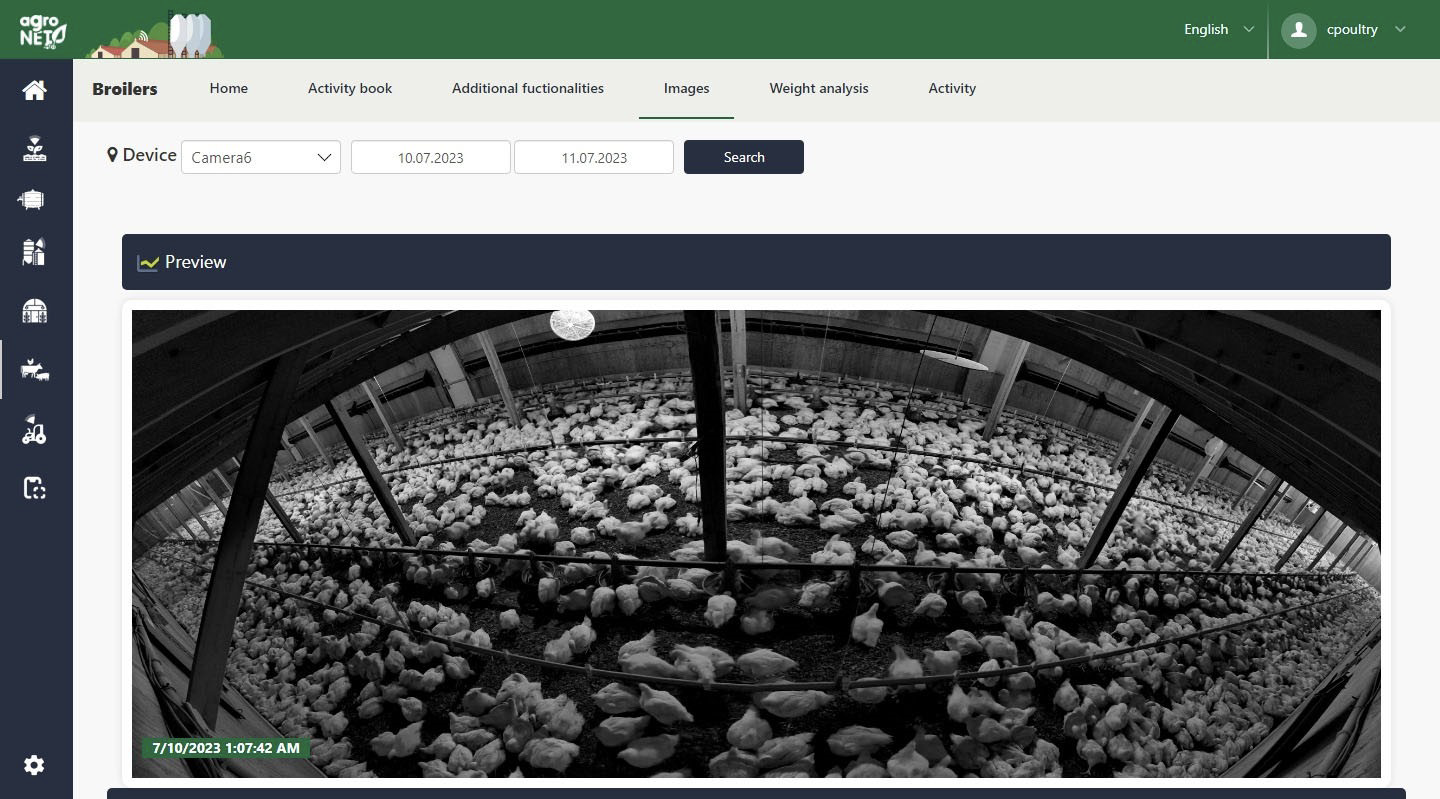

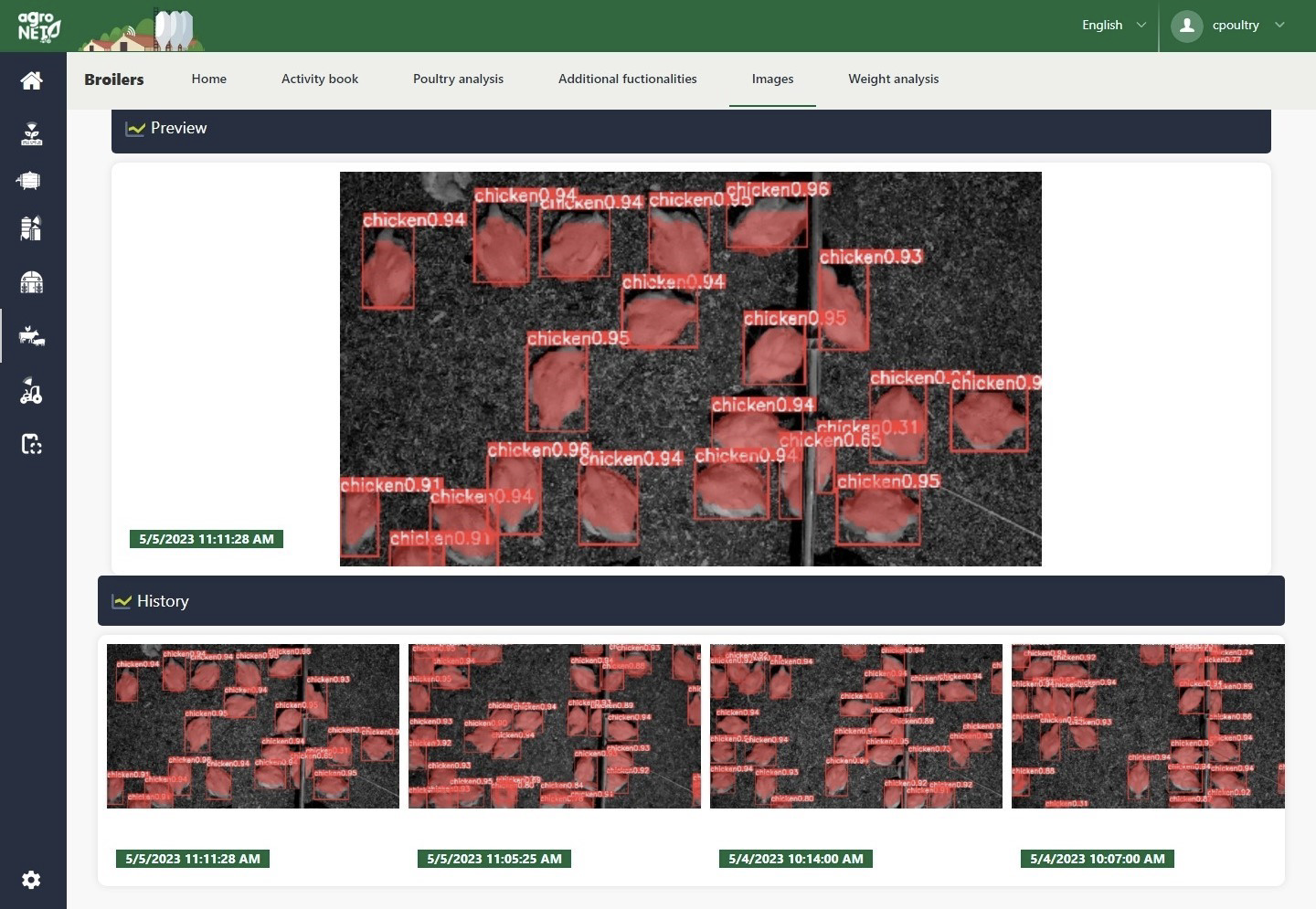

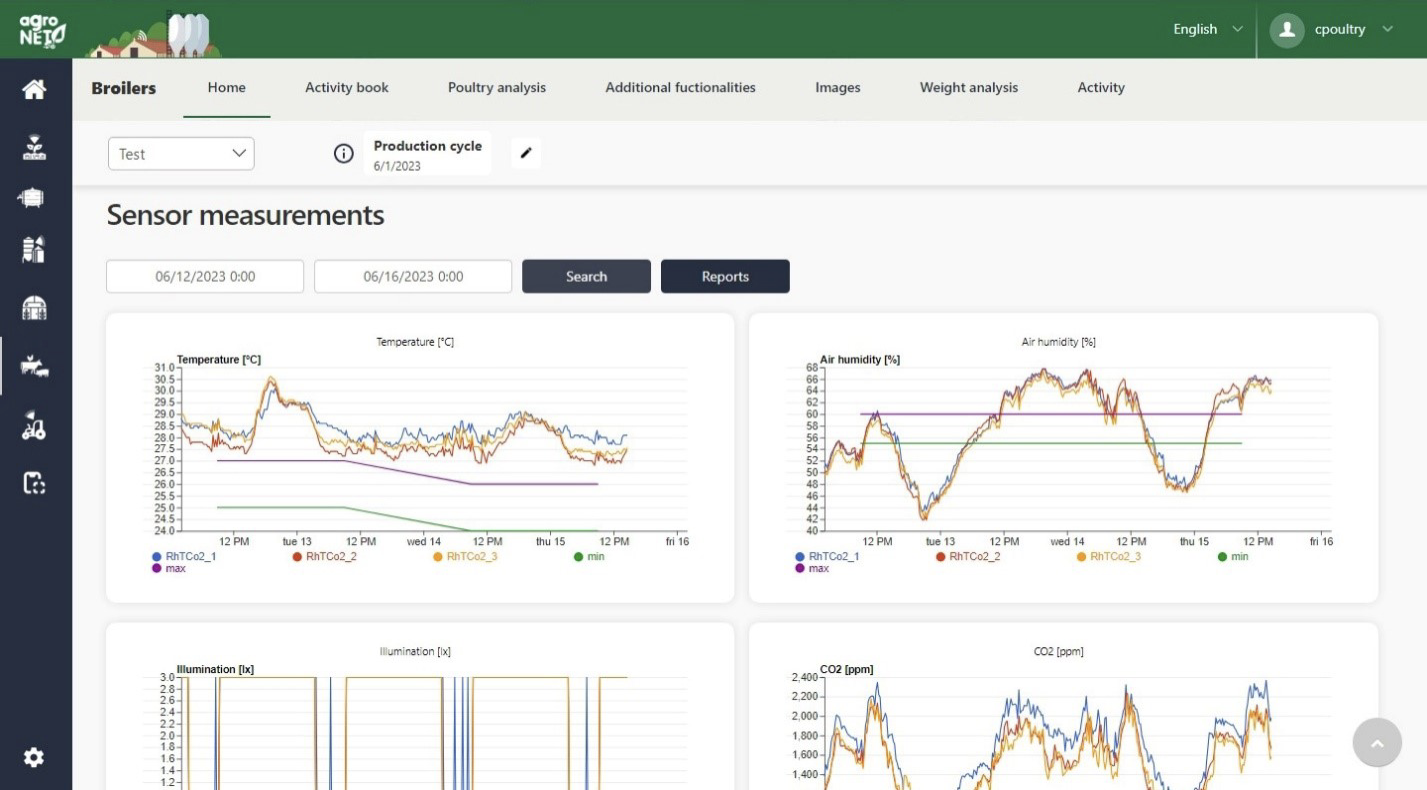

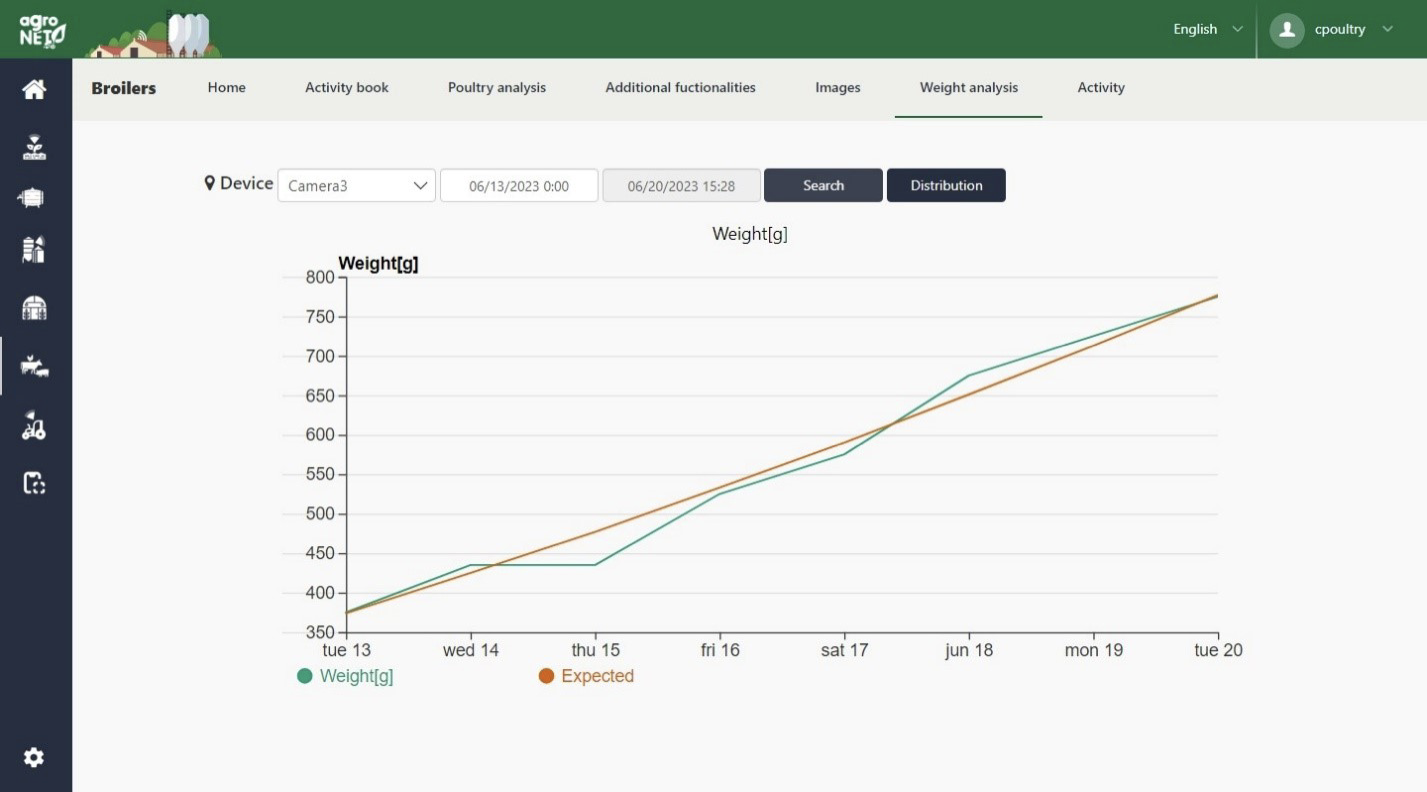

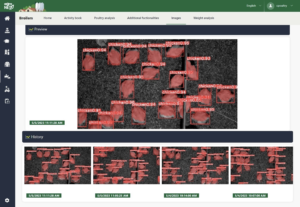

A hardware kit comprising several Seeed Studio SenseCAP LoRaWAN gateways and sensors enables monitoring of the environment (light intensity, co2, temperature, humidity) in the bars as well as selected operational parameters (e.g., water and feed consumption). A set of video cameras combined with edge ML/computer vision running on Nvidia Jetson AGX Orin is used to continuously estimate the weight of the chickens without the need for manual weighing as well as to monitor and assess the behaviour of the flock. The latter is used to assess the well-being of the chickens resulting in timely interventions and ensuring optimal animal welfare and efficient production cycles.

In addition to enhancing animal wellness and boosting production efficiency, the solution establishes foundations for creating a traceable and transparent food supply chain by creating a verifiable data set recorded in a decentralised knowledge graph for increased trustworthiness.

Why Seeed Studio’s Advanced Perception System

A set of SenseCAP LoRaWAN devices for monitoring air temperature, air humidity, light intensity, and CO2 level were deployed in a poultry barn in Canada providing 24/7 insight into ambient conditions. Additionally, a set of IP video cameras was deployed to monitor chicken behaviour and weight estimation. Video recordings are processed by NVIDIA® Jetson AGX Orin-based device, leveraging its ML inferencing capabilities to process the input and provide required information to other poultryNET subsystems for further processing and reporting.

“In many deployments, DunavNET relies on Seeed Studio’s Advanced perception system of sensor nodes, edge computing, and networking devices due to their reliability, robustness, and favourable cost-performance ratio. Positive experiences with SenseCAP devices in the past solidified our selection for the poultryNET deployments in the Montreal area, and we’re really happy with the results the project brings,” comments Srdjan Krco, Co-Founder and CEO at DunavNET.

Results

The implementation of poultryNET yields significant benefits in poultry farming. Previous results obtained from several poultry barns demonstrate a decrease in mortality rates, up to 20%, and improved feed conversion ratio by approximately 2%. Better labor force management was reported as well. Considering all previous results and anticipated return on investment (ROI) within the second or third year, poultryNET offers a highly promising solution for enhancing efficiency and profitability in poultry farming.

These promising benefits are expected to be achieved at the Sollio Agriculture’s poultry barns in Canada as well. During the first two production cycles the necessary adjustment of the solution taking into account the specificities of the poultry barn were done, and the solution outputs validated. An analysis of the results achieved with the outcomes of regular work practices will be done and the benefits calculated in the coming period.

This project also contributes to the following Sustainable Development Goals (SDG 2, 3, 9, 12, 15, and 17.)

Partners

https://dunavnet.eu

DunavNET is an innovative technology company engaged in the design and development of digital solutions. The primary focus of the company’s projects is the digitization solutions for the entire food production chain, from farm to consumer, in order to achieve more efficient production and higher quality products. As a long-standing Microsoft partner for IoT and cloud technologies, DunavNET builds its solutions on the Azure platform, providing added scalability, cost-effectiveness, reliability and security.

https://axceta.com

Axceta is dedicated to empowering its clients with the extraordinary potential of the Internet of Things and data visualization. They work hand in hand with organizations of all sizes and backgrounds, building the groundwork for data-driven strategies, streamlined operations, and smarter business decisions based on evidence.

Sollio Agriculture, the Agri-business Division of Sollio Cooperative Group, is a Canadian leader in the agriculture industry. It specialises in the merchandising of farm inputs and value-added agronomic services.It benefits from a synergy between three sectors: livestock production, crop production and grains. Present in almost every part of Canada, it has close to 1,100 employees and made $2.125 billion in sales in 2018 in Canada and abroad.

Empowering Agriculture: Regenerative Experiment in Bungoma, Kenya with SenseCAP LoRaWAN Solutions

Smart Campus: Enhancing Geography Education at Hills Grammar School with SenseCAP Sensors in Australia

Smart Poultry Farm in Canada: Enhancing Production Efficiency and Animal Welfare with AIoT Technologies

Revolutionizing Classroom Management with IoT and Raspberry Pi

About Author

Lily

Nature lover, baker, cook, DIYer, bug hunter in daily life, and wanna code. Love writing. Words are my natural expression.