Product Introduction

An experienced partner from the laser marking industry HALaser Systems has been using Seeed’s BeagleBone® Green hardware to develop a leading scanner controller card, enabling precise marking with laser and widely applied in various industry applications.

Key Info

Seeed Solution: BeagleBone® Green

Industry: Laser Marking

Solution Provider Partner: HALaser Systems

Pilot Project: Germany

Background

There is a hidden hero in the manufacturing industry, that only a few people know about, but it is elementary for nowadays production process: laser marking. This short name covers all kinds of industrial laser applications like laser welding, cutting, engraving, cleaning, and even 3D printing.

This technology is used in nearly all production processes – sometimes with visible results (such as the „best before“-date on food packages or the letters on a computer keyboard), very often with invisible results (when surfaces are treated to get a specific structure, when materials are cut for further processing when barcodes and type numbers are engraved onto components) and now often in completely own machines such as SLS/SLM 3D laser printers.

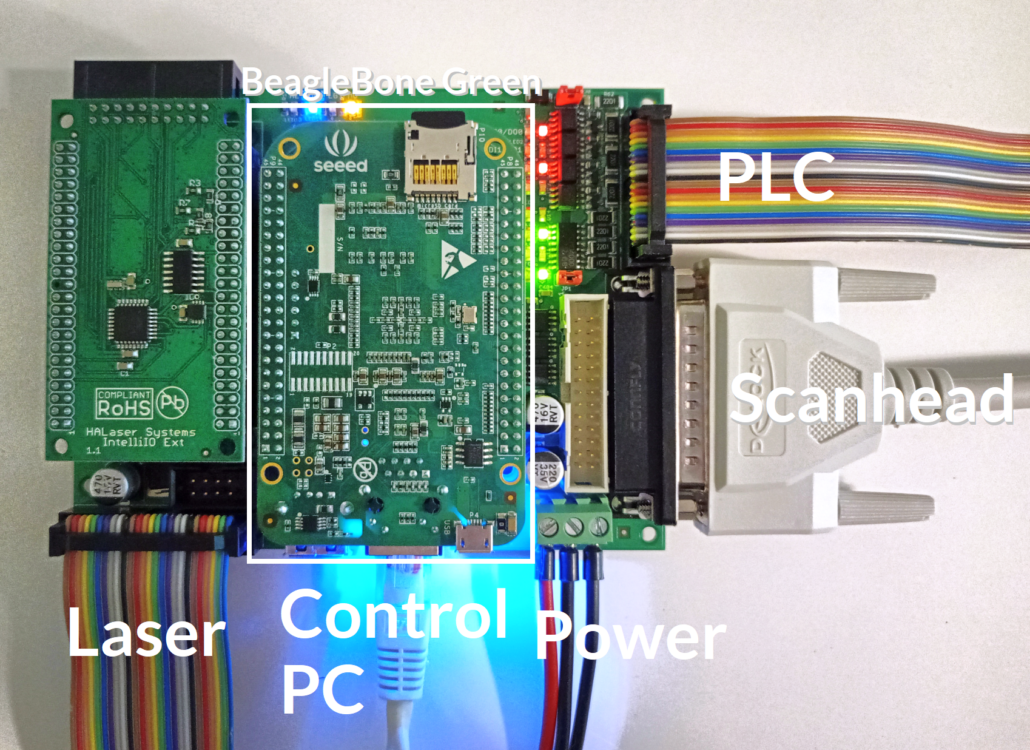

All this different stuff is done with the same base set-up of hardware: a control PC that provides the designs and production data, a controller card that switches the connected laser, and a scan head which typically consists of two digitally controlled mirrors that act as a deflection system for the laser and which are managed by this scanner controller card too.

The technically most ambitious part is the scanner controller card: it has to provide 100000 new positions to the laser deflection system (typically a compact scan head) every second and it has to switch the laser and control the laser power perfectly synchronously to these positions and with an accuracy of at least 10 usec. Besides that, it needs to communicate with the control PC, typically via USB or Ethernet. It has not only to receive the design data from there but also needs to do complex corrections with the input data in order to adjust distortions caused by the mechanics of the scan head.

Challenge

This all sounds complicated but is far away from being a complete list of features. Just to name a few other functions: there are several laser types available in the industry which have to be accessed in very different ways and have to be controlled using different signals and timings. There are further requirements such as the possibility to auto-adjust the scanhead positions during marking to e.g. follow the permanent movement of a conveyor (“marking on-the-fly”). Or there are often applications where not only the scanhead but also stepper motor axes need to be controlled – again in perfect synchronization with the laser marking application. Besides that it is also often necessary to communicate with an external PLC; either via Ethernet or via RS232/RS485 serial interface or simply via a handshake done with digital IOs.

Solution

This all requires powerful hardware with a lot of sophisticated interfaces. And this is where the AM3358 SoC comes into account, or to be more specific, the BeagleBone® Green which makes use of this chip as its main CPU and gives easy access to this SoC. Technically it provides everything that is needed: lots of interfaces, loads of freely usable IOs of different types, a powerful SoC with a main core clock of 1 GHz as well as two separate and independent realtime-cores (PRU) with 200 MHz each. Beside of that, it has a USB interface as well as an Ethernet connection.

This is why the BeagleBone® Green together with its AM3358 was chosen to develop a new, modern laser scanner controller card. Unfortunately, the first tests with this hardware have not been that promising: the system was too slow, not reacting in reproducible times and the synchronization between laser and scanhead was not guaranteed in the perfect way as it was required.

The bottleneck could be found quite fast: it was neither the BegleBone® Green nor the AM3358 SoC, it was the used operating system. Linux – as well as most other ones – is not a real-time OS and even the available software extensions, which guarantee some real-time capabilities, did not offer the accuracy and speed which was required in order to achieve the functions described above.

So the solution was clear: the board would have to be programmed directly and with no operating system in between. With the perfect documentation of the AM3358 SoC and the additional resources that Texas Instruments provides, this could be done more or less easily. And using that direct, bare-metal programming released the handbrake: now not only the overall computing performance was incredibly high, but even the realtime-capabilities have also been amazing. So with this new solution, it was possible to let the controller react on external hardware events within 0,5 usec guaranteed – which is incredibly fast. More than this, it was also possible to increase the accuracy of all internal calculations. While scanner controller cards of competitors, which do not make use of such powerful hardware, often are limited to 16 or 20-bit calculations, HALaser Systems could go with internal 26 bits – so an up to 1024 times better accuracy while adjusting the distortions of the scanhead!

Result

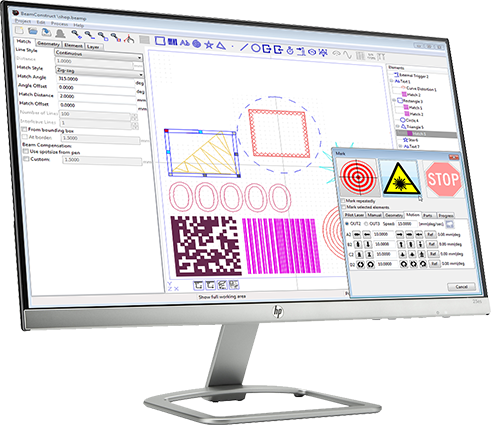

The result of all these efforts was a new generation of high-tech laser scanner controller cards. Extended by different electronics which converted the 3.3V power levels from the BeagleBone® Green, extended by several connectors which provide the control signals for laser, scanhead, and external devices like PLCs or stepper motors, HALaser Systems could release a sophisticated scanner controller card: the E1803D. Combined with BeamConstruct, a powerful laser marking software, which runs on a control PC and provides the designs to the controller, an industry-grade, highly reliable hardware set-up is available. Thanks to the design of the AM3358 and the BeagleBone® Green, the firmware running on that controller is extremely slim (in total it has a size of less than 1 MByte) and can be configured, updated, and replaced quite easily (just a few files on the integrated micro-SD-card need to be modified or replaced, so there is no nerve-racking update process via some custom communication interfaces). This hardware solution gave HALaser Systems the possibility to become one of the technology leaders in the laser marking industry.

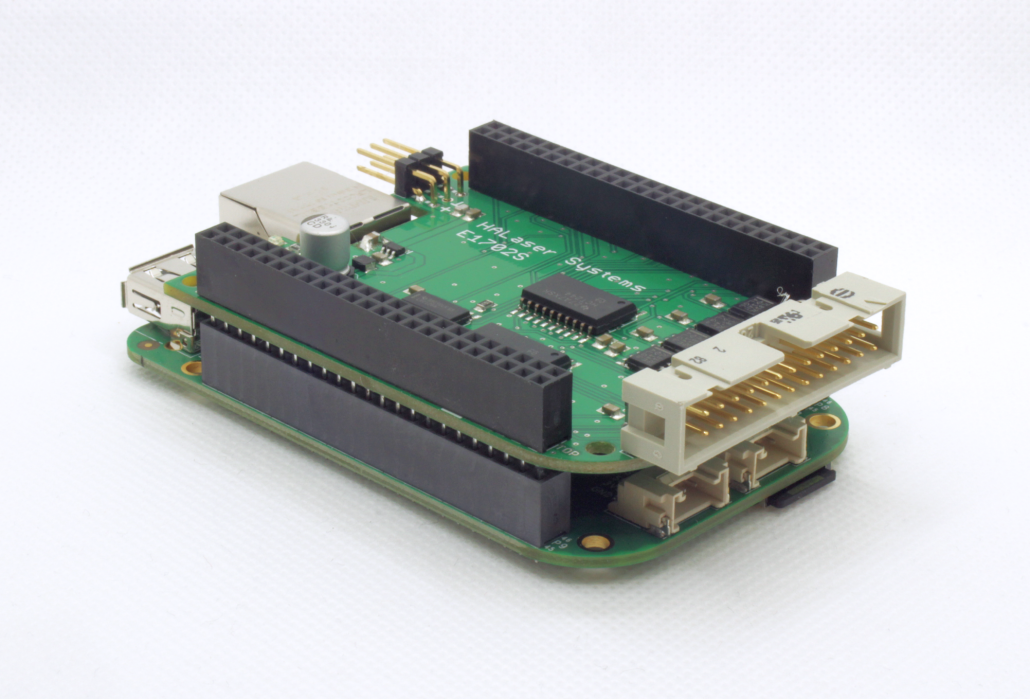

The next step was obvious and again induced by the design and capabilities of the BeagleBone® Green: while the E1803D controller card was an all-in-one device that provides interfaces and signals for all imaginable devices, lasers, and hardware types, there was the possibility to offer a product which comes “from the other end”: The E1702S scanner controller card is specialized on MOPA-, CO2, and YAG-lasers only and can communicate with 2D-scanheads only. On one hand, this is a slight limitation but on the other hand, it covers a wide range of laser marking applications and their hardware.

The big advantage of this specialized variant is its size and its incredibly low price: as it is limited to a specific number of output signals only, this controller has the size of a single BealgeBone Green plus a single cape only. Resulting from that even the hardware costs of the complete board are lower than one may expect for industrial equipment.

This incredibly small size makes the whole hardware extremely small and thus allows machine-building companies to create completely new types of compact machines. While the unique selling point of the E1803D controller card is its powerful hardware with its broad and nearly unlimited range of provided signals and interfaces, the E1702S is unique in the whole industry due to its powerful hardware and its extremely compact size. Finally, there are some more general words to say about the BeagleBone® Green: During the development of the scanner controller cards mentioned above, a lot of tests have been done by HALaser Systems. These tests not only verified the BeagleBone® Green to be usable in industry-grade hardware, but they also downgraded other comparable boards as not being that reliable and usable for industry applications with their extended requirements in terms of stability and reliability. Besides that, the price for the BeagleBone® Green is extremely competitive. So now whenever you get some new products, the chances are good, there was a BeagleBone® Green involved in some of its production steps – right because there was a laser machine involved that makes use of an E1803D or E1702S scanner controller!

Background of BeagleBone® Green Series

Seeed Studio BeagleBone® Green Series is a series of powerful SBCs jointly developed by Seeed Studio and BeagleBoard.org. They are fully compatible with the original BeagleBone® Board and have been integrated with Grove connectors, enabling users to quickly start a prototype project on this powerful platform with a bulk of Grove accessories.

BeagleBone® Green

Seeed Studio BeagleBone® Green is a joint effort between BeagleBoard.org and Seeed Studio, and it is based on the open-source hardware design of BeagleBone® Black.

It is a low-cost option that provides the compact footprint, numerous interfaces, and expandability of BeagleBone® Black while extending the development environment with on-board Grove connectors that work with the Seeed Grove ecosystem. Furthermore, Seeed Studio BeagleBone® Green is fully compatible with BeagleBone® Black capes.

Moreover, it comes with a Debian image installed on the on-board 4GB 8-bit eMMC flash storage, where you can connect the board to a 5V power supply or the USB port of your PC to easily power it up.

BeagleBone® Green Wireless

Seeed Studio BeagleBone® Green Wireless Development Board is based on TI AM335x, and is the first Wi-Fi + Bluetooth Low Energy (BLE) board from the Beagle community. It offers a Wi-Fi and BLE solution with a built-in 2.4 GHz TI WLinkTM8 module with two antennas.

It also supports AP+STA mode of communication, comes with an MRAA library, and complies with Bluetooth Advanced Audio Distribution Profile (A2DP). The board also comes with two Grove connectors, making it easier to connect to the large family of Grove sensors.

BeagleBone® Green Gateway

Seeed Studio BeagleBone® Green Gateway Development Board is a commercial-grade single-board computer (SBC). It is based on the open-source hardware design of Seeed Studio BeagleBone® Green and Seeed Studio BeagleBone® Green Wireless and combined with the onboard Wi-Fi + Bluetooth Low Energy (BLE) + Ethernet features. Which also supports various BeagleBone® Cape that can perform different functions.