This blog is written by David Roel, Head Of Sales & Marketing at Lindcom A/S

- Seeed Hardware Solution: SenseCAP LoRaWAN Sensors, SenseCAP LoRaWAN Data Logger

- Work with: Lindcom

- Industry: Oil and Agriculture

- The project deployed in: Denmark

The Challenge

In the past, one of the major challenges in installing sensor systems for remote monitoring of content within oil tanks or silos was the requirement of having to install a costly and design-wise inconvenient gateway per monitored unit. This made the installation process complicated and expensive, as each unit required its own gateway to communicate with the central monitoring system. As a result, the cost of implementing such systems was often prohibitive for many businesses and individuals.

The Solution

The Danish company Lindcom has selected the SenseCAP S2100 LoRaWAN Data Logger for its existing sensor systems for remote monitoring of content within silos as well as oil and slurry tanks. The SenseCAP S2100 is being deployed at existing as well as new installation sites.

Lindcom also has taken advantage of Seeed Studio’s SenseCAP S2103 LoRaWAN Data Logger and Sensors to develop a brand new sensor system for remote real-time monitoring of air quality.

Lindcom’s new series of MultiSense sensor systems for remote real-time monitoring includes:

- MultiSense Oil

- MultiSense Fertilizer

- MultiSense Silo

- MultiSense Air

You can click the button to download Lindom’s MultiSensor Brochure to learn more details.

The SenseCAP sensors and data loggers offer a groundbreaking, easy-to-install, and durable design – while at the same time being more cost-efficient compared to traditional gateways. Furthermore, the LoRaWAN-compatible SenseCAP sensors and data loggers open up completely new doors in terms of IoT connectivity, with much lower hardware costs to follow.

The Results

Lindcom’s MultiSense Oil system not only enables end users, suppliers, and transporters to monitor the content of individual oil tanks but also provides access to consumption history and automatically generates forecasts for the next oil delivery.

Consequently, the end user will avoid costly and stress-causing dry runs while the suppliers and transporters can utilize this data to optimize their transportation logistics and reduce their administrative costs associated with oil deliveries. Furthermore, by utilizing SenseCAP’s LoRaWAN compatibility with state-of-the-art indoor and outdoor gateways, MultiSense Oil also offers to function as an oil theft notification system.

Thanks to the SenseCAP 2103 from Seeed Studio, Lindcom has expanded its product portfolio to include MultiSense Air – a cost-efficient and easy-to-install sensor system for monitoring indoor air quality in buildings resulting in improved productivity and health as well as learning abilities not least for the sake of school children.

In conclusion, Seeed Studio’s SenseCAP technology has enabled Lindcom to improve the company’s existing sensor systems as well as expand the company’s product portfolio that comprises state-of-the-art remote real-time monitoring of parameters crucial to suppliers’, transporters, and end users’ logistics, productivity, health, and learning abilities.

About Lindcom

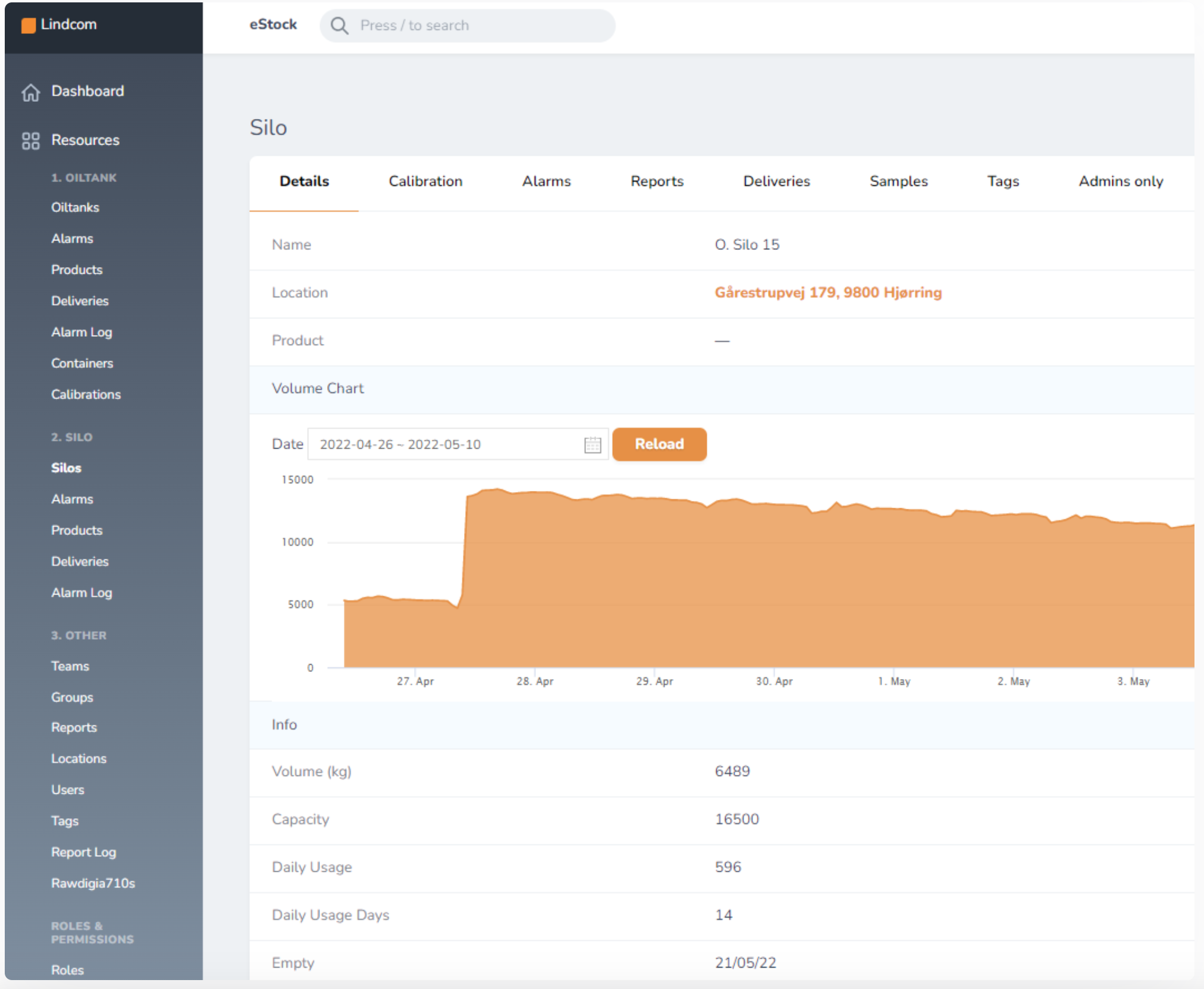

Founded in 2005, Lindcom has been a first mover in the development of sensor systems designed for remote real-time monitoring of content within oil and slurry tanks as well as silos. This is made possible through the merger of advanced sensor and data transmission technology on one hand and Lindcom’s user-friendly eStock software platform on the other hand – enabling both end users such as farmers as well as suppliers and transporters to optimize and automate their logistics.

About Author

Lily

Nature lover, baker, cook, DIYer, bug hunter in daily life, and wanna code. Love writing. Words are my natural expression.