The reTerminal has become the preferred HMI system for fruit packhouse companies.

With the solution provided by our client, reTerminal enables the functions of labelling, bin tipping, carton verification, pallet weighing, and data collection. The solution suite including custom system by our client has been deployed in 450 pieces of reTerminal, has optimized process, improved packaging efficiency and widened space of packhouse for end customers.

Client

The leading supplier of software and solution suite provider for fruit packhouses and exporters in South Africa.

Background

Our customer as a fruit packhouse and exporter solution suite provider offers a comprehensive range of end-to-end solutions. They provide a range of stand-alone applications, such as pallet weighing, pallet movement, and product labeling.

Since 2000, the company has operated end-to-end packing systems at several large fruit packhouses in South Africa, customizing packaging and labeling semi-robots. Their initial HMI solution consisted of a mountable box equipped with a raspberry Pi 3B+ and a 7-inch raspberry pi touch screen.

Challenge

Semi-automated packhouses are generally dusty, hot, and rough when not adequately ventilated. Therefore, the company wanted to offer its packhouse clients HMI meeting environmental requirements with durable design. With the surge in demand of HMI, they chased for HMI with higher performance satisfying their requirements and asked ODM services based on the reTerminal, all in one raspberry pi-powered hmi device with 5 inch screen from Seeed.

ODM Solution

Seeed was to develop the reTerminal with the functionality to be able to operate a mechanical bin tipping and labeling system that can handle loads over 1500kg, as well as adding its interfaces for a mechanical labeler with a programmable logic controller (PLC). We also integrated a capactive touchscreen and a highly responsive RFID reader for custom use.

Features:

-

Powered by Raspberry Pi CM4 32GB

-

Wi-Fi, Bluetooth, Gigabit Ethernet

-

IPS multi-touch screen with highly responsive RFID reader

-

USB Type-A, micro-HDMI, MIPI

-

Extra interface for PLC

Software Solution

The reTerminal as packhouse HMI running on our customer’s OpenJDK 1.8 Java systems that are highly configurable for different use cases. The reTerminal is also capable of communicating via HTTP and TCP with their custom Ruby framework web server as well as with packhouse equipment via TCP/IP, RS232, and Modbus. In addition, the reTerminal is capable of processing pallet labels in any given language within a range of + or – 250 milliseconds.

Business Value

The company installed about 450 peices of the reTerminal at their various client packhouse sites to perform the following tasks:

-

Installed as a labeling unit in a packing facility that processes more than 5.5 million cartons of apples every year.

-

Installed in multiple packhouses that, when combined, process over 10 million cartons of citrus fruits each year for tasks such as bin tipping, carton verification, pallet weighing, and data collection.

The reTerminal helps the client achieve a range of benefits:

reducing labor costs

optimizing process

softening building loads

improving packaging efficiency

widening space of packhouse

collecting data with Cloud

Why reTerminal

- Powered by Raspberry Pi CM4: Powerful CM4 core makes the device suitable for multitasking, satisfying various applications such as smart packing.

- Rich Interfeaces: USB Type-A ports, Gigabit Ethernet, micro-HDMI, micro-SD card slot and MIPI camera interface, offer unlimited possibilities with custom softwares.

- Connectivity: Dual-band 2.4GHz/5GHz wireless connectivity, a Gigabit Ethernet port and Bluetooth 5.0 BLE functionality help the client to collect data easier on the Cloud.

- Modular Design: By expansion, it can be used as a handheld device, mounted on other industrial machines in centralized control rooms, or as an interface or process controller.

Typical applications include:

Smart Factory

Smart Warehouse

Smart Home

Machine Learning and Edge AI Applications

IoT Controller

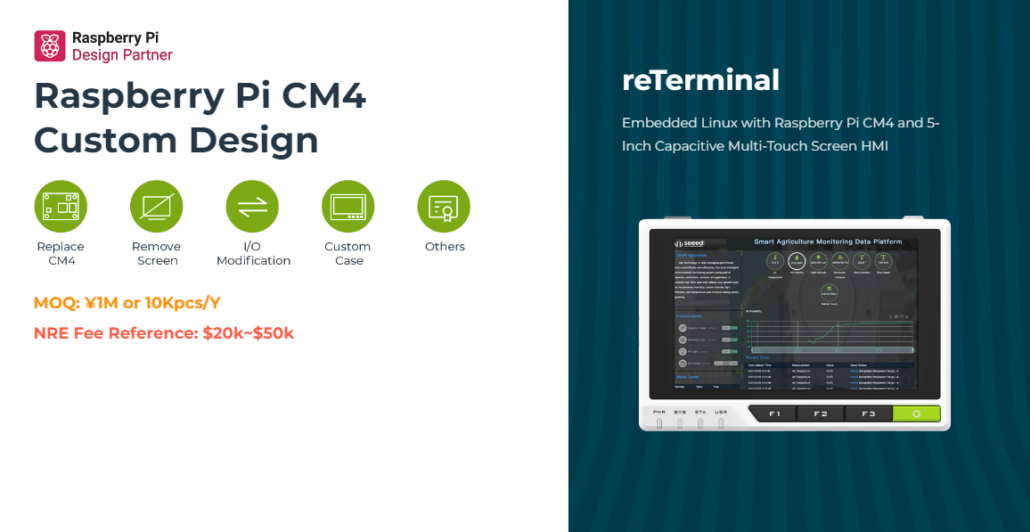

ODM Service for Open Source Hardware

With decades of ODM & OEM experience and in-depth understanding of popular open-source hardware, we are committed to assisting you at any moment and shortening your path from idea to products for emerging AIoT scenarios.

Meanwhile, we promise you the professional and flexible customization service for the existing devices – reTerminal and reRouter as well as your creative product idea based on Raspberry Pi CM4 by our engineers and product experts.