How to use Seeed Studio XIAO in your PCB Design

Seeed Studio XIAO development boards have proven immensely popular in the DIY community for their small size and powerful processing power. But fewer people are aware of an innate feature incorporated into the design of all XIAO boards and the reason behind the unique XIAO footprint. In this article, we look at the PCB design of the XIAO series of modules and show you how you can take advantage of it in your PCB designs. Here we also share the highly anticipated XIAO Eagle and KiCad libraries and footprint guidelines.

Arduino development boards have gradually been shrinking to cater to smaller, more portable applications such as wearables while at the same time packing in more processing power. The first XIAO board, initially called Seeeduino XIAO was the smallest ATMega-based development board with a USB type-C connector on the market with the previous generation, the Arduino Nano, being twice as large and featuring an outdated USB-mini socket. Not to mention, the ATMega SAMD21G18 chip packs in 3 times as much processing power thanks to the ARM® Cortex®-M0+ processor, and with 16 times as much RAM, 8 times as much flash memory and at a fraction of the cost, Seeeduino XIAO was the clear winner.

Since the original XIAO’s release, Raspberry Pi released it’s own microcontroller, COVID happened, Donald Trump was removed from office and the XIAO family grew to 5 boards. Each board is based on different chips, each with their own advantages and features from more processing power (RP2040), BLE/Wifi connectivity (nRF52480, ESP32C3) , Matter-Compliant smart home applications(ESP32-C6), and inbuilt sensors for TinyML applications (Sense).

The XIAO design

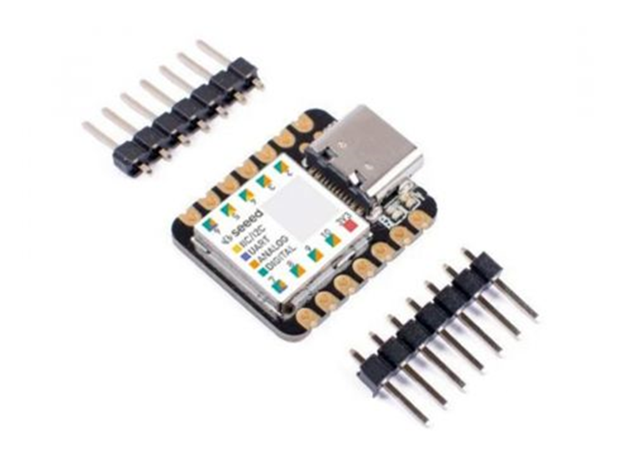

At a glance, it can be difficult to tell the difference between the XIAO boards and one may be intrigued by why they have the same unusual board shape. All XIAO boards feature single-sided assembly, meaning all components are soldered on one side of the boards (the top), and the 14 through-hole pads extend to the edge of the boards with the gold ENIG surface finish lining the side of the PCB.

PCB designers may be familiar with this hole design known as plated half-holes or castellated holes that are frequently seen on modules such as Espressif ESP32 WiFi modules or breakout boards. The purpose of these half holes is to allow the modules to be soldered flat on the surface of printed circuit boards like other chips and components in a surface mount fashion. This reduces the need for plated through holes which could take up much board real estate, increase the height of the boards and increase soldering costs.

XIAO boards use the same traditional design features to allow developers to easily move from development board to production module, removing the need to design the chip into the final product from scratch, while being small enough to have a minimal impact on product size. The built-in USB type-C port is an added bonus, removing the hassle of connecting jump wires to reprogram the device and also serving as an easy power source. More development boards are adopting the same design techniques such as the Raspberry Pico to ease the transition from prototype to mass production.

The standard XIAO footprint means that XIAO modules are interchangeable, enabling greater flexibility and greater functionality. For example, the Seeed Studio SAMD21 (original XIAO) now dwarfs in processing power compared to XIAO RP2040, and is in plentiful supply, unlike the ATMega SAMD21 chip. The growing popularity in RP2040 across the community means greater Arduino support, all in all making RP2040 a tempting alternative for traditional Arduino chips.

How to solder Seeed Studio XIAO boards to your PCB?

The hybrid through-hole/castellated hole pad design gives designers more options when approaching PCB board design and assembly.

Direct through-hole soldering:

Solder two 7 pin, 2.54mm pitch male headers to the boards and solder the other ends to plated thru-holes on the PCB board. This method is simple as assembly of small quantities can be achieved quickly with a common soldering iron. However, for mass production, automating assembly is more difficult.

Carrier board method:

Solder two male headers to the XIAO boards as in the previous method, and solder two female headers to the PCB or insert the male pins to a breadboard for prototyping. With this carrier board/shield-style set-up, one can easily switch XIAO modules without having to desolder the modules.

Surface Mount soldering:

Using the appropriate land pattern on the PCBs, the XIAO module can be surface mounted using the traditional solder paste/reflow oven soldering technique. The make XIAO modules suitable for automated assembly and compatible with common mass production methods.

How to incorporate XIAO boards into your PCB design?

In response to repeated demand, we have created Eagle and KiCad libraries for the XIAO series, and for other PCB design software, we have released recommended land pattern guidelines for you to create your own footprints.

Autodesk Eagle

Seeed Studio XIAO series symbol and footprint libraries are available to download from GitHub, or download them directly from Eagle’s online managed libraries.

KiCad

Seeed Studio XIAO series symbol and footprint libraries are available to download from GitHub.

Recommended Land Patterns datasheet

Download the Seeed Studio XIAO Series Package and PCB Design datasheet for recommended land patterns and dimensions.

We hope that the libraries will encourage more users to take advantage of the XIAO’s flexible assembly capabilities and assist product developers in using XIAO in their designs. The libraries were brought to you by Seeed Fusion’s Design for Assembly (DFA) engineers, so you can be assured they are production ready.

Seeed Fusion Turnkey PCB Assembly service can cater to your PCB assembly needs. From parts procurement, PCB manufacture to assembly, Seeed Fusion has the expertise and supply chain connections to ensure the success of your project. Whether you need parts from Digikey, Mouser or cheaper Asian alternatives, high PCB layer counts, exotic substrates or low MOQs, Seeed’s flexible and agile manufacturing capabilities can to cater to all needs.

Now all PCBA orders include Design for Assembly (DFA) review and PCB Design for Manufacture (DFM) review absolutely free. Try our smart online quotation platform and get a complete quotation in seconds.