Hey community,

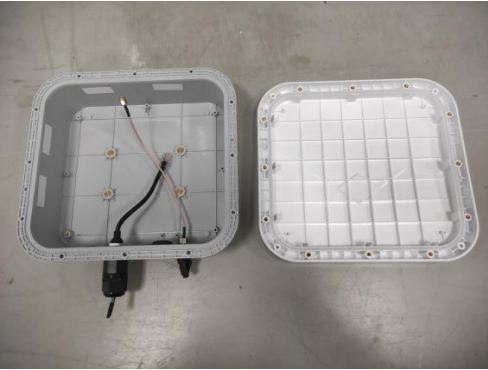

The new entry of our Open Manufacturing series is now ready to go! A few weeks ago we released the SenseCAP Outdoor Enclosure, which is made of Polycarbonate. Even though it’s IP66 rated, many of you may wonder how reliable it is when it’s applied in various real-life scenarios. So for this episode, let’s take a deep dive into its reliability testing!

Reliability testing is to ensure that the quality and durability of a given product are consistent with its specifications throughout the product’s complete lifecycle. Considering the scenarios where the SenseCAP Outdoor Enclosure usually is applied, the reliability test we conducted this time included three typical usage scenarios: testing for Outdoor Enclosure, testing for the Outdoor Enclosure Attached with SesneCAP M1 and POE Splitter, and testing for User Scenario with Holding Pole. SenseCAP Outdoor Enclosure successfully passed all the 14 tests!

No idea of what exactly these tests are? Let’s break them down and have a deep dive into the tests.

01 Reliability Test of Outdoor Enclosure

As you can see from the table above, the testing can be categorized into two types: Environmental Testing (including temperature, humidity, salt mist, waterproof and dustproof test) and Structural Strength Testing (such as drop test and vibration test).

Let’s shed the light on Environmental Testing first. The set of environmental and use conditions varies quite a lot since the enclosure owners are locally globally and using the product in different scenarios. To make sure it will operate in all expected using environment, the Environmental Testing is a series of tests to evaluate the reliability of the Outdoor Enclosure’s material, structure, assembly, made process performances by simulating different combinations of temperature, humidity, salt mist, and more.

For the High Storage Temperature & Humidity Test, the SenseCAP Outdoor Enclosure is put into a constant temperature and humidity test chamber for 48 hours, where the temperature reaches 85℃ and humidity at 95% RH respectively. And for the Low Storage Temperature test, the temperature reaches -40℃.

For the Operational Tests, the SenseCAP Outdoor Enclosure is put into an environment of high temperature and high humidity (the temperature at 85℃ and humidity at 95%RH) to test out its operation. After 48 hours of tests, it passed the tests.

And not only that, but we also conducted a Temperature Shock Test to ensure the adaptability and destructiveness of SenseCAP Outdoor Enclosure. First, place the sample into the temperature Shock Chamber. Second, set the temperature to -40℃ for 1 min, and change it to 85℃ for 1 min, noted that the conversion time is less than 10 seconds and totally proceeding 24 cycles. Finally, check the samples after the test. The test curve is attached below:

Salt Mist Test (also known as Salt Spray Test) is especially recommendable for products that are used (in operation) close to the coast or at sea. To simulate corrosive effects, the SenseCAP Outdoor Enclosure is exposed to salt mist in a salt spray test chamber with the temperature at 35℃ and humidity at 85%. During the test duration of 7 days, there’s no rust in the enclosure.

Water-proof Testing is especially recommendable for products that are used (in operation) outdoors, especially in the storming rainy weather. To simulate raining effects, the SenseCAP Outdoor Enclosure is exposed to gushing water at various angles from a sprinkler. You can watch the video on the left.

During the test duration of three minutes, no water entered the enclosure and the product inside the enclosure worked normally and passed the test.

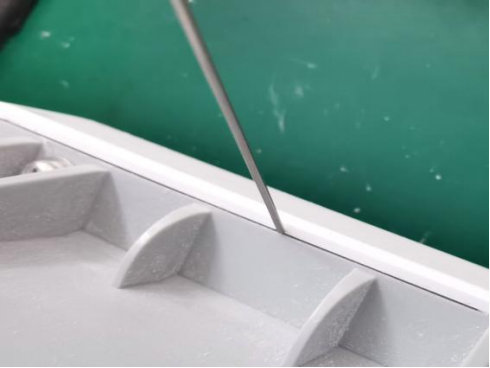

Dust-proof Testing is also indispensable for fieldwork devices. Keeping the sample in a state of negative pressure, we used a test probe with a diameter of 1mm to test the gapping part of the enclosure with a force of 1N, which was continuously tested for 2 hours in a dust-proof test box.

As it’s tested out, the test probe cannot enter into the sample and no dust entered into the sample.

Then it’s time for Structural Strength Testing. As you can get from the testing name, it is a series of tests to ensure the structure of the tested products are reliable and durable during their life cycle. Since the SenseCAP Outdoor Enclosure is designed to protect the installed hotspot, we carried out drop testing and vibration testing twice: one for the enclosure itself and the other for the enclosure with SenseCAP M1 installed inside.

Vibration Testing has been performed for 3 hours in total, 1 hour for each of the X\Y\Z axis, with the POE splitter fixed by adding foam.

You can watch the video on the left vividly showing what testing machine we used and how we tested it.

Three hours later, we found no deformation in appearance, no loose screws, and no looseness of the whole machine, thus passing the tests.

For Drop Testing, the drop height is 1M, and the sample has been dropped for 2 cycles with 1 corner and 6 faces successively. Its appearance has been inspected per cycle, and the structure and appearance of SenseCAP M1 have been checked after two test cycles, so as to make sure there are no defective products. After the testing, the Enclosure showed no deformed, cracked, or damage, and SenseCAP M1 worked normally.

02 User Scenario Test

To simulate the usage scenarios of most users as realistically as possible, we carried out the User Scenario Test (Holding Pole) with four combinations, covering devices like SenseCAP M1, SenseCAP M2 Basic Version, SenseCAP M2 4G Version, POE Splitter in SenseCAP Outdoor Enclosure. Specific tests are shown in the table below:

Taking extreme weather into consideration, firstly, we conducted an Operational Test in Extreme Weather, using SenseCAP M1 & POE Splitter in Outdoor Enclosure as a sample. We put it into an environment of high humidity (the temperature at 50℃ and humidity at 95%RH) and low temperature (the temperature at 0℃) to test out its operation. After 48 hours of tests, it passed the tests.

Then, we carried out a Continuous Running Test for two months so as to ensure the reliability of both the enclosure and the gateway devices assembled in the enclosure. With temperature recorded of both environmental temperature and the temperature inside the Enclosure, we found devices with enclosure protection are just a little higher than the environmental temperature by 5℃. Moreover, it has been shown that POE splitter weakens heat dissipation in an acceptable range.

After being tested through all these tests, the Outdoor Enclosure still works with the following features:

No deformation, no looseness, no cracking on the enclosure

No peeling and discoloration of the surface paint

No rust on metal parts or short circuit

No deformation cracks on the enclosure

The tested SenseCAP M1 and M2 can be turned on and off

Operation with all functions

This’s pretty much about all the topics that we want to cover for today. Any feedback or any other details that you want to explore but we forget to include? Comment to let us know.

As always, we can’t wait to see what you make. Shoot us a tweet @seeedstudio, or let us know on LinkedIn, Discord, or publish your project on our Project Hub on Hackster. Please be safe out there, be kind to one another, and we’ll see you next month with even more exciting news!

About #OpenManufacture

Why are we doing this? Manufacturing has long remained a challenge for developers to mass manufacture their projects at scale. So to leverage the open-source spirit, we’re opening up and showing our work about the entire process of how we manufacture our #IoTIntoTheWild new products at our factory. With all these, we’d love to make manufacturing as accessible as possible and keep the whole community posted on the product updates at the same time.

I´m about to try it out in Austria with negative degrees (Celsius) in winter (with Sensecap M1) . I Hope the heat from the device / cpu will be enough to keep it within the operating temperatures inside the enclosure (?). Worst case is killing the Sensecap M1 at -10 degree celsius – i dont know.

At least interesting to find out..

Keep us posted then!