Behind the Scenes of SenseCAP M2 LoRaWAN Gateway: Reliability Testing

Hey community,

Ready for the 2nd entry of our Open Manufacturing series? Since we published the 1st entry on how we carried out the performance testing of SenseCAP M2 LoRaWAN Gateway, we got lots of comments asking for updates! Today, we’ll still focus on the DVT (Design Validation Test) phase in the product development, and look into how reliable the SenseCAP M2 is for all IoT projects on Helium, The Things Network, and more LoRaWAN-based networks!

Yes, the keyword today is Reliability Testing! Reliability testing is to ensure that the quality and durability of a given product are consistent with its specifications throughout the product’s complete lifecycle.

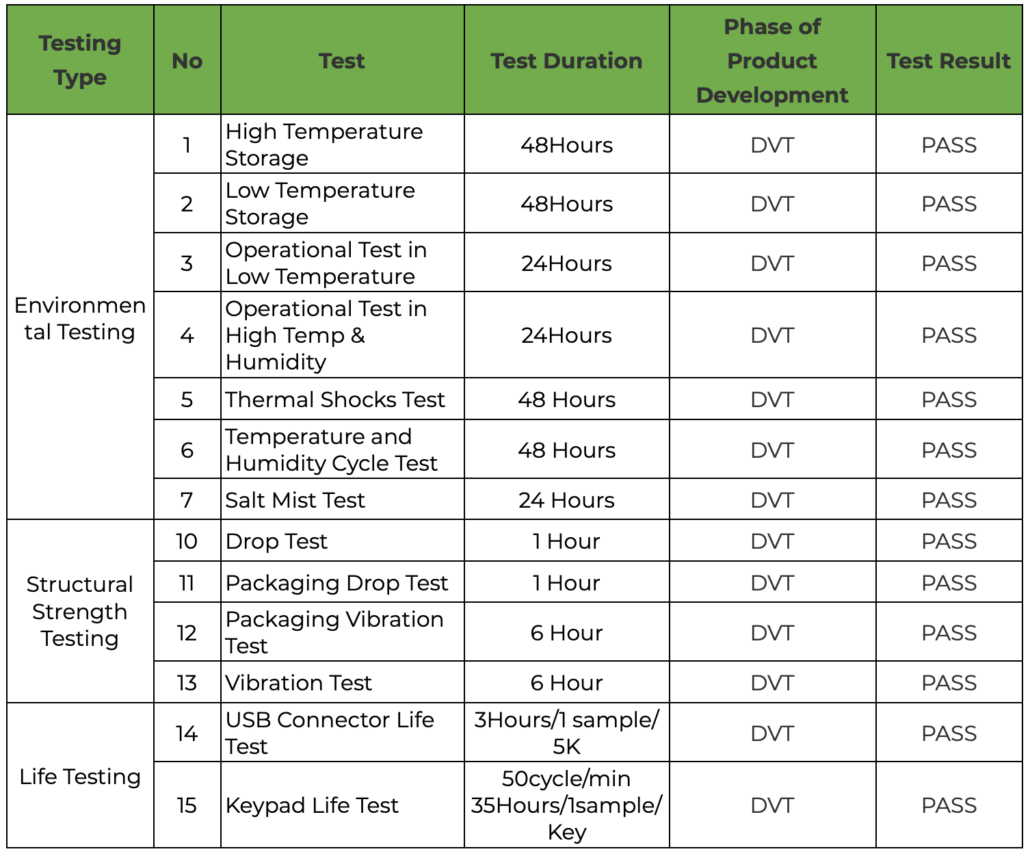

As SenseCAP M2 is a LoRaWAN Gateway that can be applied in various real-life scenarios, we’ve conducted 3 types of reliability testing for the product: Environmental Testing, Structural Strength Testing, and life testing. All passed!

Have no clue about these tests? Let’s break them down and have a deep dive into the tests.

01 Environmental Testing

The set of environmental and use conditions or stresses varies quite a lot since the SenseCAP M2 owners are locally globally and using the product in different scenarios. To make sure it will operate within the expected customer environment and under all SenseCAP M2 owners’ use conditions, Environmental Testing is a series of tests to evaluate the reliability of SenseCAP M2’s material, structure, assembly, made process performances by simulating different combinations of temperature, humidity, salt mist and more.

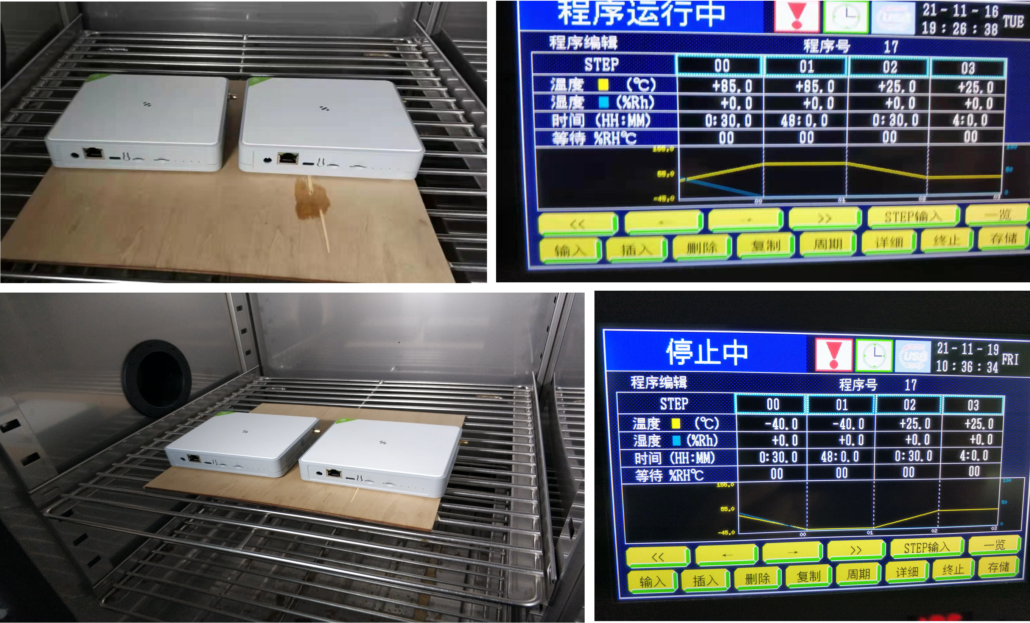

For the High Storage Temperature and Low Storage Temperature test, SenseCAP M2 is put into a constant temperature and humidity test chamber for 48 hours, where the temperature reaches 85℃ and 0℃ respectively.

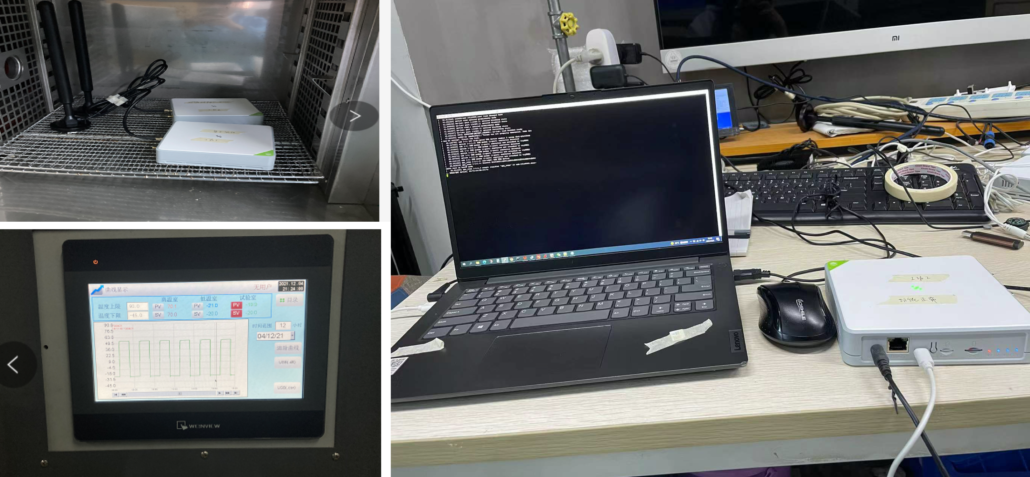

For the two Operational Tests, SenseCAP M2 is put into an environment of low temperature (at negative 20℃), high temperature, and high humidity(the temperature at 55℃ and humidity at 85%RH) to test out its operation. After 24 hours of tests, SenseCAP M2 passed both tests.

When doing the Thermal shocks test and the Temperature and Humidity Cycle Test, SenseCAP M2 was put into the thermal shocks test chamber for 48 hours. The temperature and humidity in the chamber shifted from as high as 55℃ to as low as negative 20℃.

Salt Mist Test (also known as Salt Spray Test) is especially recommendable for products that are used (in operation) close to the coast or at sea. To simulate corrosive effects, the SenseCAP M2 is exposed to salt mist in a salt spray test chamber with the temperature at 35℃ and humidity at 85%. During the test duration of 24 hours, the chamber will spray salt mist that contains 5% sodium chloride to the SenseCAP M2 every hour.

After being tested through all these 7 tests, the SenseCAP M2 still:

- Can be turned on and off

- Operating with all functions

- No deformation cracks on the enclosure

- Buttons are still working with flexibility and agility

- No rust on metal parts or short circuit

- No peeling and discoloration of the surface paint

02 Structural Strength Testing

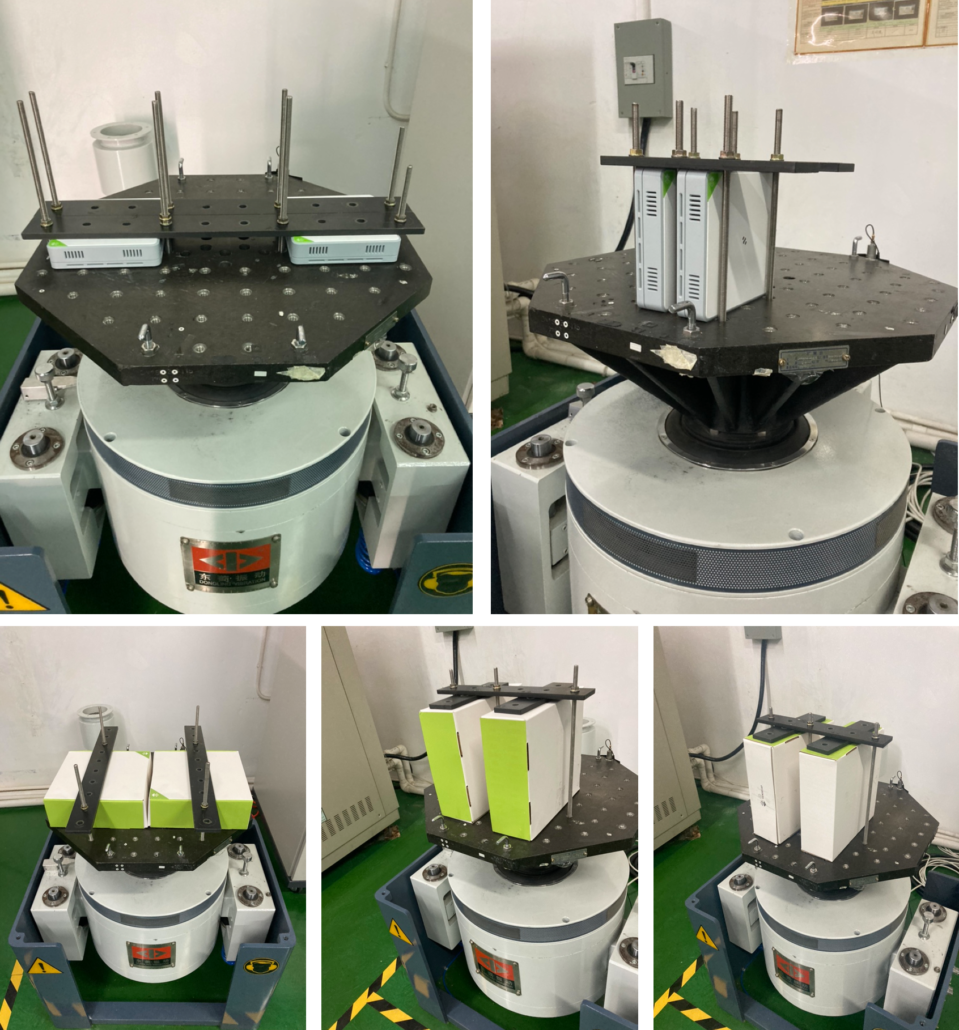

As you can get from the testing name, Structural Strength Testing is a series of tests to ensure the structure of the tested products are reliable and durable during its life cycle. Since the SenseCAP M2 comes with a package, we carried out a drop test and vibration test twice: one for the SenseCAP M2 device and the other for the device in its package.

During the Vibration Test, SenseCAP M2 was put on an instrument that can generate vibration at various vibration frequencies. After 8 hours of testing, the device that functions normally passed the test.

Drop Test means dropping the product from a specific height to test if the product and its package can still remain their function. For these two tests, we set the height at 1 meter and dropped the test sample 12 times with different angles. As it tested out, SenseCAP M2 and its package are both qualified.

03 Life Testing

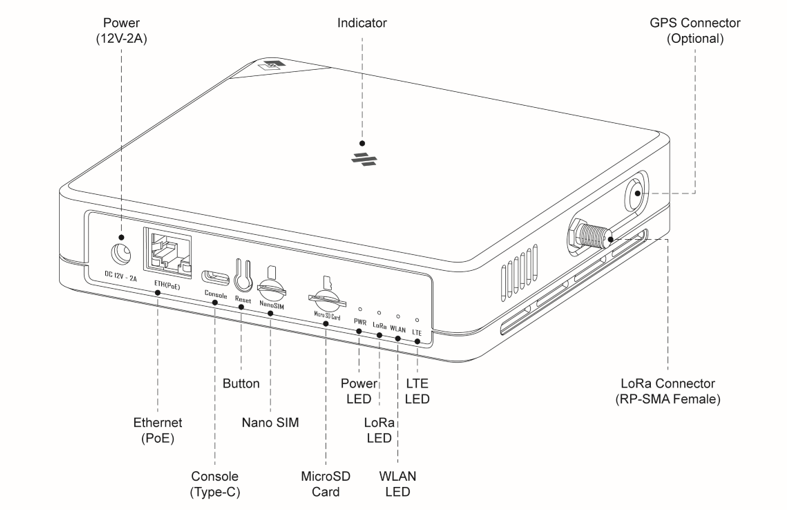

When we need to understand how long a product will operate without failure, the appropriate test approach is called life testing. since SenseCAP is designed for various real-life IoT applications, it’s really important to make sure that it will operate as long as we expected, especially for its 2 very commonly used parts: the Type-C Console Connector, and the Button.

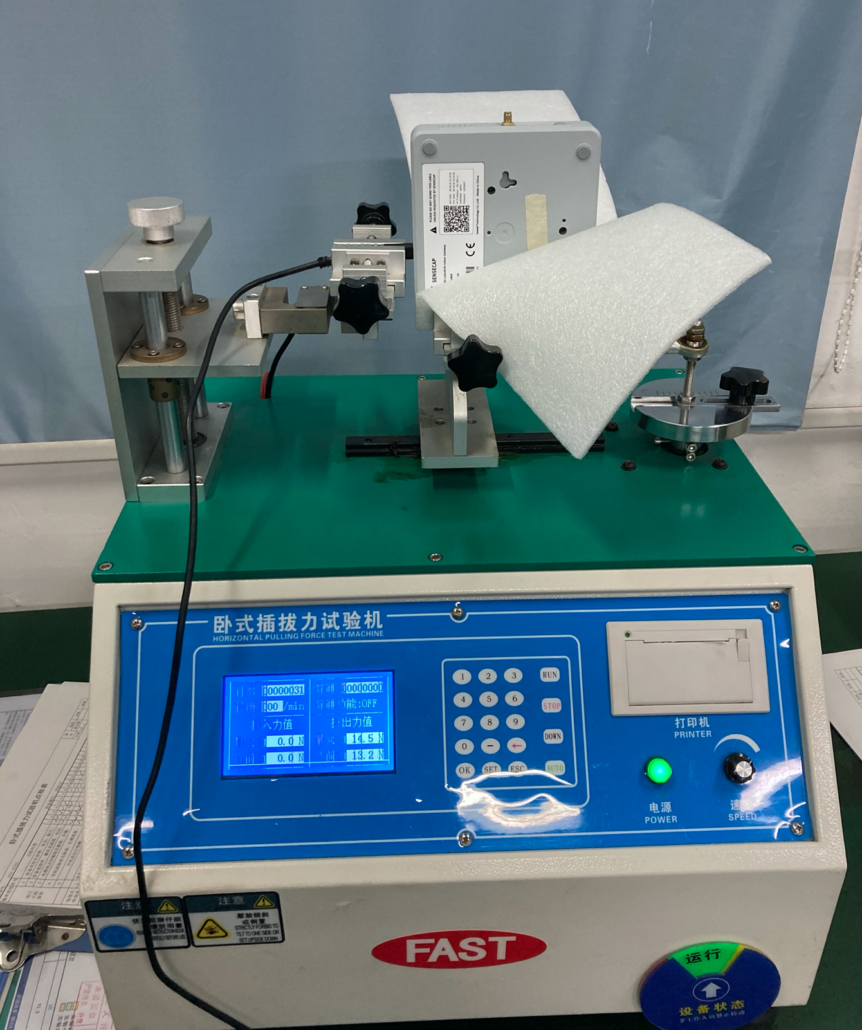

To do the Console Connector Life Test, we used a Horizontal Pulling Force Test Machine to plug and unplug the Type-C wire 100 times. After that, the connector functions as normal.

As for the Button Life Test, a Mobile Phone Button Life Tester is applied to press the power button of SenseCAP M2 multiple times. Each button got 30,000 times of press in total with a pressure of 6-8N. After testing, the button is still working properly, and the shape of the button remains in-deformable.

This’s pretty much about all the topics that we want to cover for today. Any feedback or any other details that you want to explore but we forget to include? Comment to let us know.

? Spoiler. Stay tuned for our next entry, where we will take you to the production line of SenseCAP M2: mass production time! Until then! 🙂

#About Open Manufacture

If you’re new to this Open Manufacturing series, here is a brief intro. It’s a blog series where we share every important development and manufacturing phase of our #IoTIntoTheWild new products. Why are we doing this? Manufacturing has long remained a challenge for developers to mass manufacture their projects at scale. So to leverage the open-source spirit, we’re opening up and showing our work about the entire process of how we manufacture our #IoTIntoTheWild new products at our factory. With all these, we’d love to make manufacturing as accessible as possible and keep the whole community posted on the product updates at the same time.

#Previous Entries

- Behind the Scenes of SenseCAP M2 LoRaWAN Gateway

- Open Lab: How I Tested the Communication Distance of Seeed Studio XIAO ESP32C3

- The Reliability Testing of SenseCAP Outdoor Enclosure

- How We Chose and Tested the Enclosure Material for Industrial LoRa Sensor Probe

- IP66 Dustproof and Waterproof Testing of SenseCAP, Seeed’s Industrial IoT Products for Smart Agriculture

- How We Tested the Long-Range Communication of Seeed’s Industrial IoT Product SenseCAP LoRaWAN Series

- High-Low Temperature Testing of SenseCAP Industrial IoT Products

- How We Tested The Industrial LoRa Light Intensity Sensor

- How We Tested the Performance of SenseCAP ONE Weather Station

Get Support and Updates from Seeed Community