TinyML Talk on May 6: Industry 4.0: Predictive Maintenance using Arduino Portenta H7 and Edge Impulse

By Lily 3 年 agoJoin us at the next TinyML meeting at 7 AM on May 6 (PT). We’ll have Manivannan Sivan, Lead engineer in the Computer Vision Department at Valeo, as the speaker to talk about Industry 4.0: Predictive Maintenance using the Arduino Portenta H7 and Edge Impulse.

Edge computing, the Internet of Things, and machine learning for ultra low powered devices are having a profound impact on the manufacturing sector, leading to increased automation, greater efficiency, and the emergence of valuable new business models, thereby driving the transformation of the manufacturing sector into Industry 4.0. Although digital technologies can be applied throughout the value chain, the most significant benefits are likely to be gained in predictive maintenance.

What is Predictive Maintenance?

The concept of predictive maintenance refers to a proactive maintenance strategy that uses data analysis tools and techniques to assess equipment conditions to facilitate proactive maintenance measures. Its goal is to optimize the utilization of maintenance resources. Having the ability to predict when a specific part will fail allows maintenance managers to schedule maintenance work only when it is required, avoiding excessive maintenance and avoiding equipment breakdowns, respectively. In an ideal circumstance, predictive maintenance should reduce the frequency of needed maintenance.

Picture source: Smart Asset Maintainance

Why is predictive maintenance so essential?

An effective predictive maintenance program can significantly enhance the maintenance and reliability of an operation. According to a report by PwC, preventative maintenance practices in factories could reduce costs by 12%, increase uptime by 9%, decrease safety, health, and environmental risks by 14 %, and extend the life of an asset by 20 %.

How does predictive maintenance function?

In general, a predictive maintenance system consists of three main elements: tracking, communication, and a predictive system.

1. A condition-monitoring sensor has been installed to transmit real-time data about performance and machine health.

2. IoT technology enables the communication between machines, software solutions, and cloud technology.

3. A predictive data model is fed with all the data to predict failures.

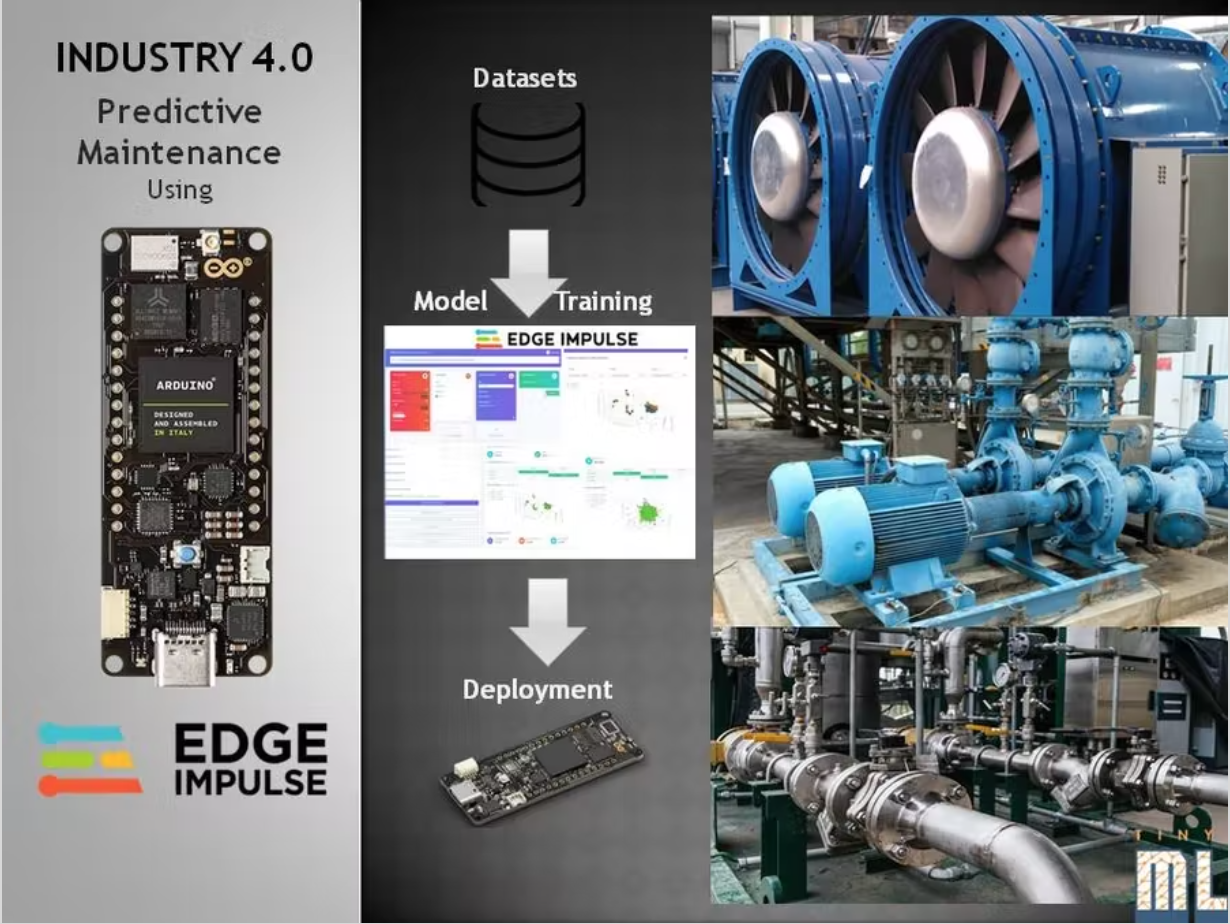

TinyML Talks on May 6: Predictive Maintenance using Arduino Portenta H7 and Edge Impulse

Are you interested in learning more?

Join us at the next TinyML meeting at 7 AM on May 6 (PT). We’ll have Manivannan Sivan, Lead engineer in the Computer Vision Department at Valeo, as the speaker to talk about Industry 4.0: Predictive Maintenance using the Arduino Portenta H7 and Edge Impulse.

During the talk, Manivannan will explain the potential of TinyML in Industrial 4.0. This TinyML model uses Arduino Portenta H7 and Edge Impulse to predict the anomalous operation in Industrial machinery like Pumps, valves & fans. For Industrial machinery audio datasets, the proposed method uses open-source datasets – MIMII. This dataset contains audio of malfunctioning industrial machines. It contains the sounds generated from four types of industrial machines, i.e. valves, pumps, fans, and slide rails. Each type of machine includes seven individual product models*1, and the data for each model contains normal sounds (from 5000 seconds to 10000 seconds) and anomalous sounds (about 1000 seconds). The model is trained using Edge Impulse with a 1-D Convolution layer and followed by neural network layers.

About the Speaker

Manivannan is a lead engineer for Valeo’s computer vision platform. Currently, he is pursuing his Ph.D. at the VIT University in “computational prediction methods of vehicle control stability.”. His passion for TinyML led him to develop numerous applications, ranging from elephant conservation to the automotive industry. He holds an Indian patent for his work on “An Ohmic heater for food preservation by the flash process using a low voltage IGBT based single phase inverter module.” One of his TinyML models was selected as the “Top 5 machine learning model” in the Elephant Edge competition.

Last but not least, we are calling for speakers for our more upcoming tinyML Shenzhen meetups and talks. If you want to be a speaker to share with the global community your journey of tinyML, please click here to apply.

About Author

Lily

Nature lover, baker, cook, DIYer, bug hunter in daily life, and wanna code. Love writing. Words are my natural expression.