How to find a good low volume PCB Assembly manufacturer?

After completing the preliminary design of the product, product designers may need to outsource PCB assembly to a professional PCBA manufacturer to both verify prototypes and produce the final product. For smaller businesses and low volume runs, it may be difficult to find a good PCB Assembly manufacturer willing to accept low volume orders. This article will analyze the top four reasons for this and provides suggestions on finding the best one for your needs.

1. The scale of the company does not match.

For start-ups, small companies, design houses or just one off projects, it may be unrealistic to find a large factory similar to Foxconn for small-batch manufacturing or prototyping. Most likely, your order quantity may not reach their Minimum Order Quantity or MOQ. You should focus on searching for specialist small and medium-sized PCBA manufacturers. Only these PCBA manufacturers will accept orders for small-batch prototype of PCBA, and will provide services more tailored to small batches.

2. The price difference is too big.

The price of small-batch PCBA and prototyping is completely different compared to mass production. It is recommended that you talk to a few factories to compare quotations, and research the other services they offer to fully weigh in the pros and cons of each. Price is not everything. A complete turnkey service that takes care of parts procurement can save you a lot of hassle and minimize production complications for the inexperienced. More and more factories have transparent cost calculators online to help with your search. Seeed’s instant online quotation system can calculate the entire cost, including the cost of components in seconds. Click and get a quote.

3. Geographical factors

The area where a PCB assembly facility is located can have a significant impact on costs. Much of PCB manufacturing and assembly involves a combination of automation and skilled labor, and the cost of each can be very high, especially for small batch and agile manufacturing facilities. Companies may have an incentive to manufacture PCBs in areas where the cost of labor is lower. For example, labor costs in China are much lower compared to Western Europe and North America, but the lower cost does not have to be at the expense of quality. Areas like Shenzhen China, the Silicon Valley of hardware, have ample experience and good connections to produce quality products at high speed for the international market. Fierce competition has also brought prices down while pushing companies to improve their offerings. You should also consider the cost of getting parts to the assembly facilities and any international restrictions.

4. Future production plan and schedule.

Most manufacturers that are willing to accept prototyping and small-batch orders do so in the hope that the clients will also choose them to handle mass production at a later stage. So many PCBA factories are willing to invest time and energy to help with prototyping in the early stages of product development. Manufacturers will be interested to know what your production plans are and can help prepare in advance. For example, they may suggest changes to the design to make it more production friendly or help stock-up on materials with long lead times. They will also be more willing to provide extra services or discounts for a long-term partner. Likewise, manufacturers do not like one-off orders or customers who only care about getting the lowest price.

To find a good small-batch PCB Assembly manufacture partner for your needs, you should pay attention to finding a partner that matches your interests and the scale of your expected production volume, as well as being able to satisfy your budget and quality standards.

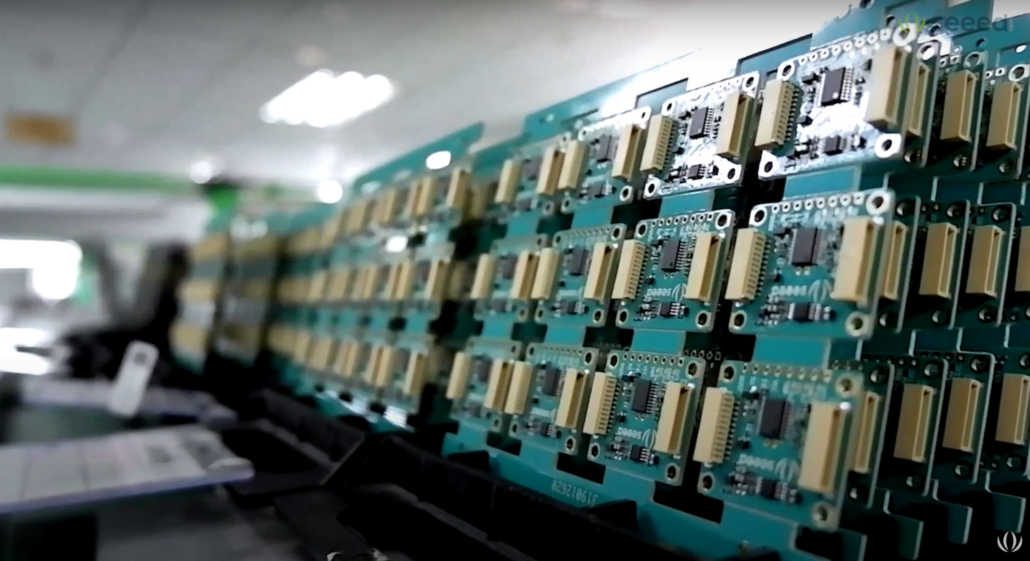

Located in Shenzhen China, Seeed Fusion is the ideal choice for low-volume PCB Assembly needs. Engaged in agile manufacturing for over 10 years, Seeed provides a complete all-in-one service including components procurement, PCB manufacture and assembly. Now, you can get prototyping costs refunded when you prototype the design with us, up to 6% of the mass production value. Learn more about Seeed’s PCBA capabilities.