How We Tested the Performance of SenseCAP ONE Weather Station

The design quality, structure and material of SenseCAP ONE Weather Sensor are proven through extensive performance tests and will be introduced in this blog.

To serve the increasing demand for better measurements, Seeed has developed industrial-grade IoT environmental monitoring devices, especially our SenseCAP product series, to suit a wide range of specialized applications both indoor and outdoor.

The design quality of all SenseCAP Industrial IoT devices is proven through extensive performance tests. We firmly believe that quality control is fundamental for environmental monitoring sensors, and is the necessary final stage before the release of all Seeed products.

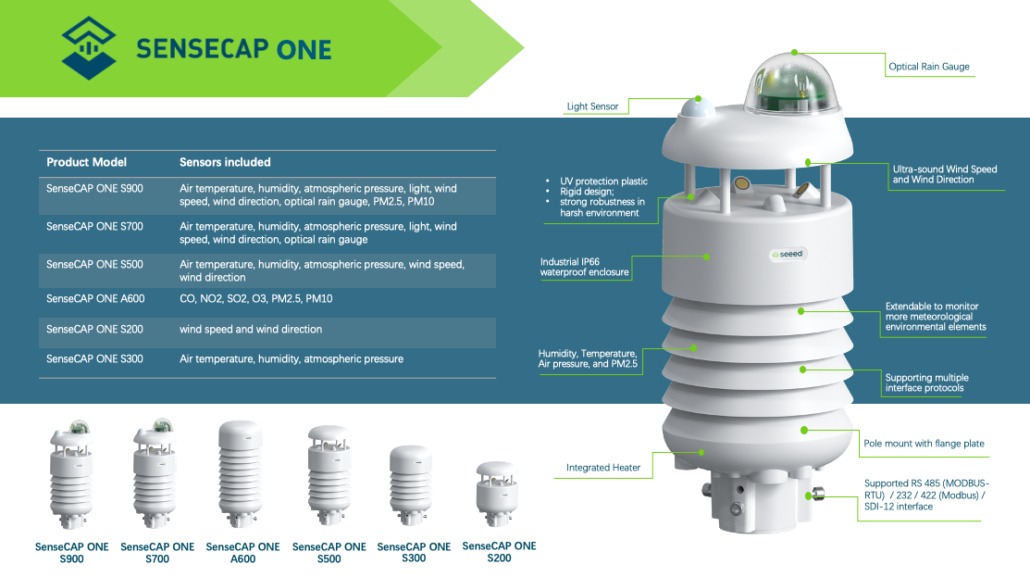

Last year we introduced our new friends to SenseCAP Industrial IoT product line – SenseCAP ONE All-In-One Compact Weather Sensors. Currently, SenseCAP ONE S700 7-in-1 Compact Weather Sensor is available on our Bazaar e-commerce store. S700 7-in-1 Weather Sensor measures parameters including air temperature, relative humidity, barometric pressure, light intensity, rainfall (optical), wind speed, and wind direction (ultrasonic), so it is an ideal option for applications in rough conditions in outdoor scenarios: agriculture, smart cities, smart traffic, just to list a few. Excitingly, SenseCAP S500 and S900 will be available soon!

After more than a year of performance testing of each component of the environmental sensors, and continuous self-diagnosing processes before handing each sensor to our customers, here we write this blog to share our testing process with you all and how we evaluate SenseCAP ONE weather sensors to ensure their data quality, consistency, and reliability.

Testing Robustness – Meeting Industrial IoT Quality Standard

To accurately measure the weather parameters in various and diverse conditions, ensuring the high quality of enclosure material, design, and manufacturing of devices is always the prerequisite. Weather Sensors, which are the core components supporting the well-functioning of weather stations, are mean to be durable, reliable, and maintenance-free to constantly record data in even extreme environments for years. SenseCAP ONE Compact Weather Sensors are designed to meet the Industrial IoT standard and to minimize the need for post-installation maintenance and service. The tests listed below give you an overview of why the SenseCAP ONE series of devices can survive in an extreme environment to confront difficulties.

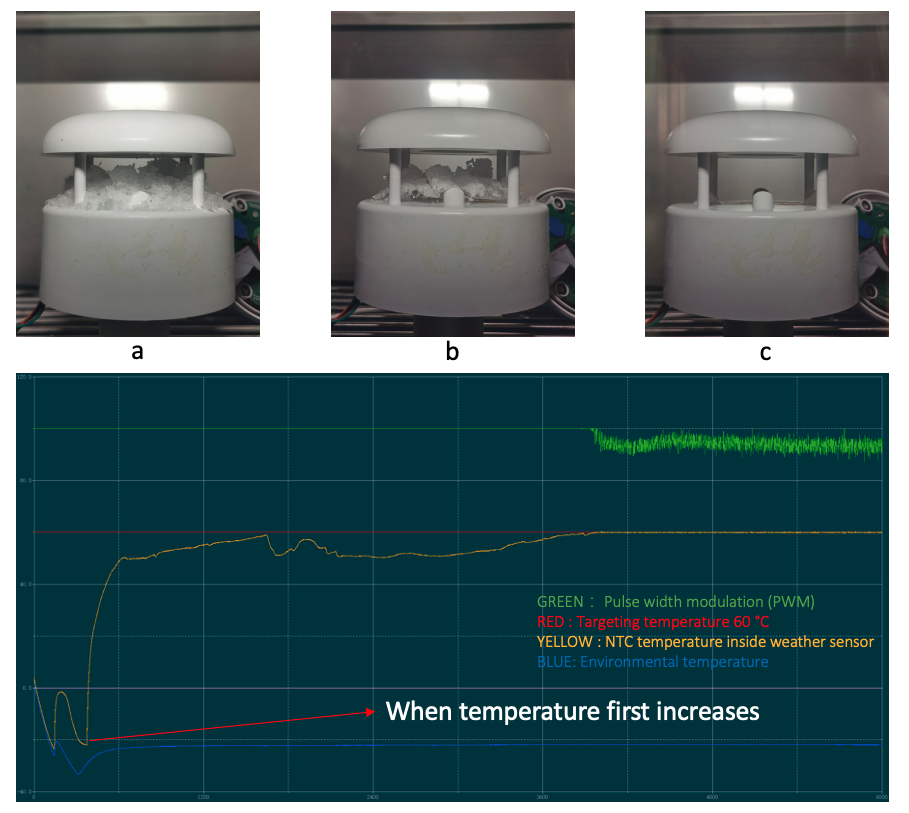

‘Ice Removing’ Test – Evaluating Heater Performance

Sensors might be inaccurate in a low environmental condition. To solve such a problem, every weather sensor goes along with an integrated heater to ensure its normal operation by eliminating the obstacle between ultrasonic probes that prevents measurement. To test the performance of the integrated heaters, sensors are placed into freezing testing environment. By enabling the heater, engineer recorded the changing of NTC temperature inside the weather station until the ice cube and snow melt completely.

Test Result:

- No deformation of the enclosure.

- Integrated heater functions normally to increase and constantly maintain the temperature inside the sensor to create an appreciated inner environment for each component to function well.

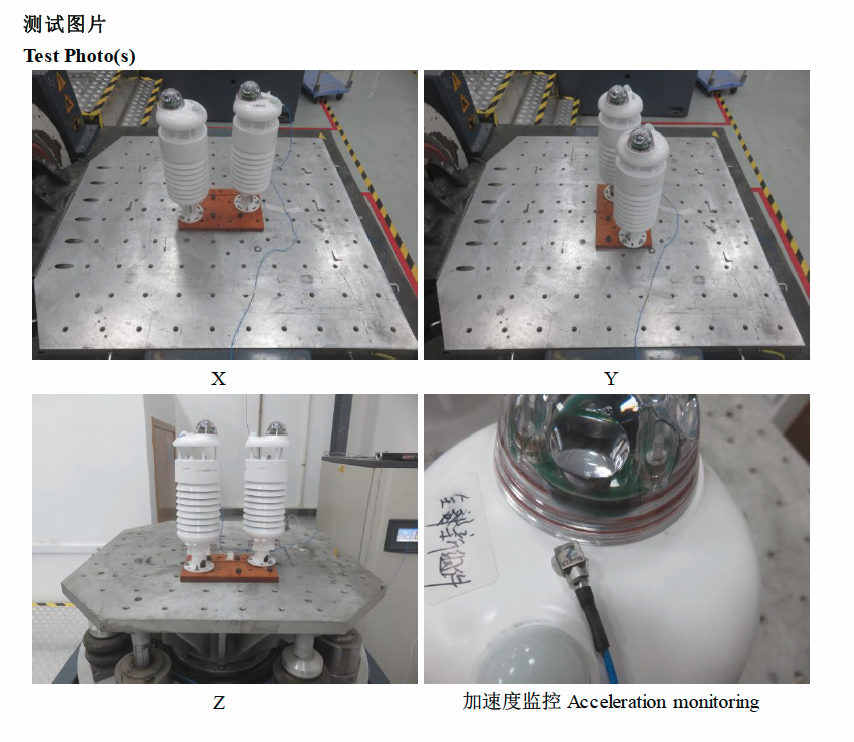

Vibration Test – Whole Machine Structure Evaluation

Weather Stations have to survive in extreme weather with meteorological hazards like gale, storms, and hurricanes. Transformation process also involves in unavoidable deterioration of infrastructure. Having strong robustness against any possible damage on functionality is a must. Therefore, simulating extreme environmental condition to see whether there exist constructional and functional destructions after testing helps evaluating the quality of a weather sensor.

Test Result: The structure of the prototype has no crack, no damage, and no deformation. No screw loosening during and after the test. And all functions remain normal during and after the test.

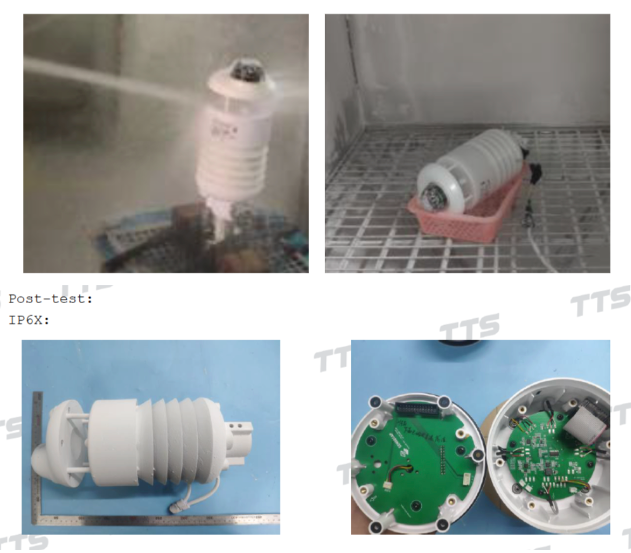

IP66 standard – Waterproof and Dust-proof Test of Enclosure Materials

Like what we did to our SenseCAP LoRaWAN product series in previous testing post, SenseCAP ONE also was examined by waterproof and dust-proof tests. These testings provides index for evaluating whether the enclosure material used by the devices meets the IP66 standard. All sensors are protected by the enclosure, or they might lose efficacy if water and dust get inside and disrupt the electricity. Weather sensors which will be exposed to the outfield environment to provide first-hand data to researchers, industry expertise and practitioners, ought to meet the standard that no possible interruption by dust and water could exist.

Test Result: no send or water is able to enter the gaps of our weather sensor sample.

High-Low Temperature Test – Efficiently Against Weather Shocks

The selection of sensor’s enclosure material involves multiple dimensions of considerations. There should strike a balance between strength and flexibility, as the weather sensor should stands firmly against the turbulence and possible extreme weather events. Thus, verifying the reliability of sensor’s structure and material properties under Thermal Shock Chamber is necessary. We placed the weather station inside such a chamber with 85℃ and 90-95% humidity in 72 hours to see how our SenseCAP ONE Compact Weather Sensor perform.

Test Result: All functions are normal and there exists no deformation, mechanical damage and crack in product.

Testing Sensor Component

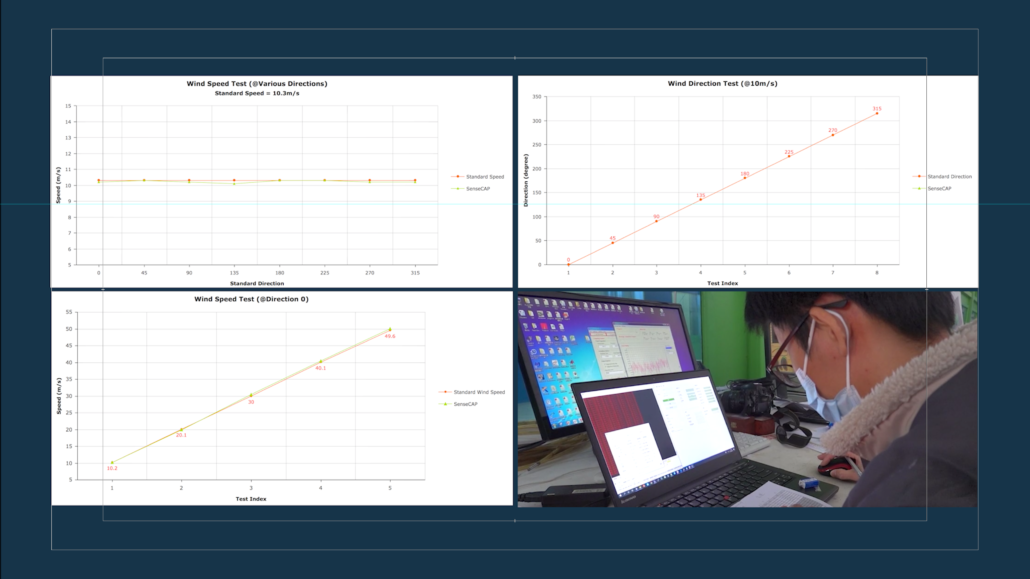

All-in-one weather station integrates multiple sensors independently detect different environmental parameters and provide reliable data for its users to analyze on a convenient basis. Therefore, testing each sensing component is also necessary. Today we will show you the Wind Channel Test which examines the functionality of ultrasonic wind direction and wind speed sensor in the SenseCAP ONE Compact Weather Sensor.

Ultrasonic Wind Direction & Wind Speed Sensors – Wind Channel Test

The wind tunnel is an important equipment testing product in the development process. Developers use a wind tunnel to examine the accuracy of the ultrasonic wind sensor Seeed Studio developed. The maximized windspeed in this wind tunnel is 60 m/s. To withstand the high wind speed while recording accurate data ultrasonically, the weather sensor has to meet all strict requirements for solid performance, structural design, and material selection.

The result reveals that the parameters SenseCAP ONE recorded generally match the standard wind speed and wind direction, showing its great performance in the testing.

Certificates and Test Reports:

Aging Test – Crucial Step for Quality Control

Aging test is the last but indispensable step before shipping our industrial-grade products to our customers. By constantly evaluating all the functionality of the SenseCAP ONE weather sensor within 72 hours, we finalize the quality control of the weather sensors to prevent possible damages and breakdown before this series of products get ready to use.

That is all! Hope this blog gives you a better understanding of most of the tests our SenseCAP ONE Compact Weather Stations have undergone and their superior reliability and durability! We look forward to applying the SenseCAP ONE weather sensors in more scenarios with your supports!

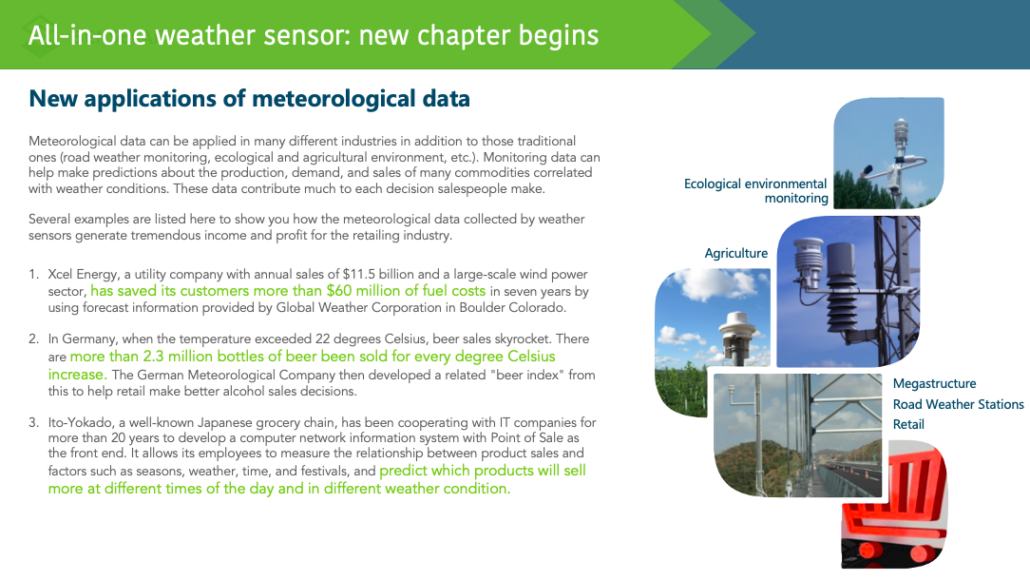

Some incredible applications of Weather Stations:

Learn More:

- Learn more about SenseCAP

- SenseCAP ONE Series Meteorological Sensors Wiki

- Weather Station with SenseCAP ONE S700 & Raspberry Pi

- New Release | SenseCAP ONE, Industrial-grade Compact Weather Stations for Meteorological Monitoring

- How We Tested the Long-Range Communication of Seeed’s Industrial IoT Product SenseCAP LoRaWAN Series

- IP66 Dustproof and Waterproof Testing of SenseCAP, Seeed’s Industrial IoT Products for Smart Agriculture

- High-Low Temperature Testing of SenseCAP Industrial IoT Products

SenseCAP Use Cases:

- SenseCAP LoRaWAN Use Case: Baoneng Cold Storage Warehouse – Industrial IoT solution for Food Traceability

- Autonomous Greenhouse Challenge at Wageningen University in the Netherlands

- Smart Poultry Farming in Beijing, China

- Smart Musang King Durian Farming in Pahang, Malaysia

- Sustainable Agriculture | Global IoT Education Initiative in the US, Australia, & Congo, etc.

- Smart High-Mountain Tea Plantation in Sichuan, China

- Smart Sweet Melon Greenhouse and Weather Station in Guangxi, China

- Environmental Monitoring in Stockholm, Sweden

- Data-driven Tourism in Guangdong, China

- Smart Greenhouse Growing Tropical Fruits in the North, in Shandong, China

- Smart Outdoor Triticale Farm in Hebei, China