Getting Started with Gas Sensors in Industrial IoT

If you are building an industrial Internet of Things (IoT) system, you should definitely consider adding a gas sensor to your arsenal. As their name suggests, industrial gas sensors are used to sense the presence and measure the various properties of gasses in industrial contexts. Despite this relatively simple-sounding application, gas sensors can play a critical role in building safe and reliable industrial processes! Thus, look no further and join us in today’s article to learn all about how to get started with industrial gas sensors in IoT!

In this article, we will cover:

- How do Gas Sensors Work?

- Use Cases & Benefits of Gas Sensors

- How to Choose a Gas Sensor

- Pushing the Limits of Gas Sensors with TinyML

How do Gas Sensors Work? – Operating Principle

Gas sensors are equipped with a sensing surface that responds in different ways to the presence of a test gas. For example, the surface may experience a change in resistance, capacitance, mass or optical characteristics, which is in turn used to determine the magnitude of the test gas concentration. Naturally, different materials used for the sensing surface will in turn allow for different gases to be detected!

Example: Electrical Gas Sensors

An electrical gas sensor’s ability to detect different gases depends on the chemiresistor used in the sensor, which is a material that changes in electrical resistance according to changes in its surrounding chemical environment.

One such chemiresistor that is commonly used is none other than Tin Dioxide (SnO2). Tin Dioxide is known as an n-type semiconductor, meaning that it carries free electrons to conduct electricity. Under normal circumstances, the abundant oxygen in surrounding air attracts these electrons away to the surface of the tin dioxide material. With a lack of free electrons within the material to conduct electricity, the current measured across the material is close to zero.

On the other hand, when the sensor is in the presence of toxic or harmful gases, these gases serve as a reducing agent to oxygen, separating them from the free electrons. These free electrons now return to the material where they are able to now conduct electricity. Thus, the current which we measure across our sensing material will now be greater, indicating the presence of harmful gases!

Some other popular types of gas sensors are shown in the table below!

| Type | Operating Principle |

|---|---|

| Electrochemical | Changes in current, voltage, capacitance/impedance: 1. Voltammetry (including amperometry) 2. Potentiometry 3. Chemically sensitized field-effect transistor 4. Potentiometry with solid electrolytes for gas sensing |

| Electrical | Metal oxide conductivity Organic conductivity Electrolytic conductivity Heterojunction conductivity (Schottky diode, FET, MOS) Work function Electric permittivity (capacitance) |

| Mass Sensitive | Changes in the weight, amplitude, phase or frequency, size, shape, or position: 1. Quartz crystal microbalance 2. Surface acoustic wave propagation 3. Cantilever |

| Magnetic | Changes of paramagnetic gas properties |

| Optical Devices | Changes in light intensity, color, or emission spectra: 1. Absorbance 2. Reflectance 3. Luminescence 4. Refractive index 5. Optothermal effect 6. Light scattering (Raman scattering, plasmon resonance) |

| Thermometric (Calorimetric) | Heat effects of a specific chemical reaction. Changes in temperature, heat flow, heat content: 1. Thermoelectric 2. Pyroelectric 3. Catalytic bead (pellistors) 4. Thermal conductivity |

Use Cases & Benefits of Gas Sensors

Now that you know more about how gas sensors work behind the scenes, you’ll be happy to know that they actually have numerous applications, especially in industrial IoT. Here are some examples where gas sensors might be useful or even essential for your IoT systems!

1. Monitor & Maintain Operating Conditions

Are gases important to the context in which your application will be working? In lab, agriculture, or even manufacturing environments, the types and quantities of gases present can be key indicators of whether things are working as they should!

In some other applications, it might even be critical to closely monitor the composition of the surrounding gas. For example, the amount of CO2 or NO2 found on precision farms can greatly affect the yield of crops, and should thus be closely monitored and maintained. Adding a gas sensor to your industrial IoT system allows you to take advantage of wireless technologies to remotely monitor and collect such data to more effectively meet your requirements!

2. Improve Process / Workplace Safety

Many businesses are still choosing to install industrial gas sensors as part of their safety systems. Well, when you consider that gases are one of the most dangerous hazardous materials encountered in industry, this comes as no surprise.

With most toxic industrial gases being both colourless and odourless, they have the potential to be silent killers and must be detected through sensors and meters. Incorporating gas sensors in your IoT-enabled safety systems can allow employees to be reliably alerted of any potential hazards like toxic gas leaks, significantly improving workplace safety and preventing the worst – a loss of life.

3. Developing Smarter, Greener Cities

With the increasingly pressing impacts of climate change, it is more important than ever for businesses and industries to fulfill their part to save the environment. A transition to greener industries and cities is expected to take time, requiring both research into new, cleaner technologies and a deep reflection upon current industrial practices.

Nonetheless, developing eco-consciousness with the use of IoT monitoring is an excellent place to start. With a better understanding of how our actions impact the environment, we can then identify processes that need to be improved and to better mitigate their impacts. Amongst this, air quality measured by gas sensors is an extremely important metric to understand environmental pollution!

How to Choose a Gas Sensor

If you’re in the market for a gas sensor, Seeed has a great variety of industrial-grade products that will deliver effective and robust performance for your IoT systems, including gas sensors.

Introducing Seeed’s SenseCAP Series

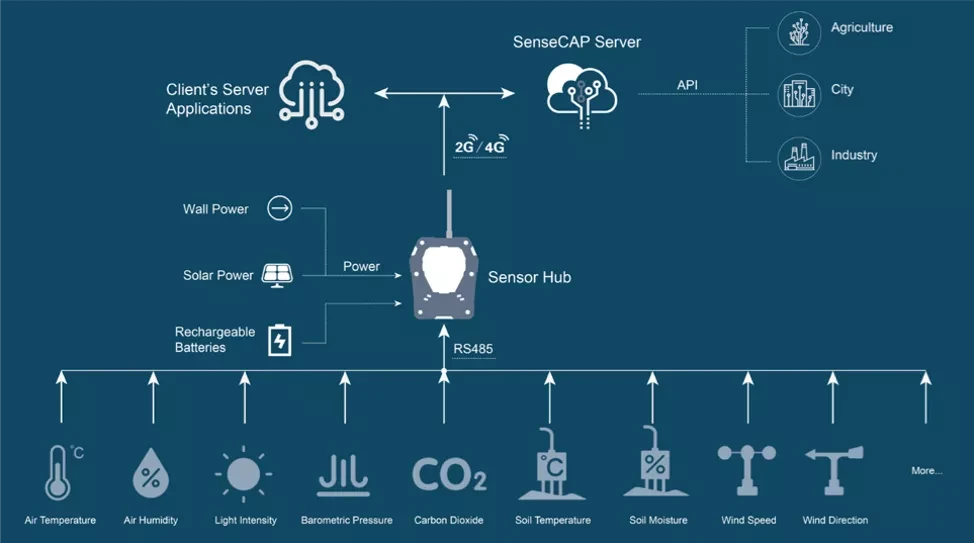

Amongst Seeed’s Industrial IoT (IIoT) products, the SenseCAP series focuses on products which enable wireless environmental sensing. From smart agriculture, precision farming to smart cities, SenseCAP provides hardware (sensors, data-loggers, gateways), software (SenseCAP portal, mobile application, API) and versatile compatibility with different communication protocols, including LoRa, 4G, NB-IoT!

SenseCAP Sensor Hub 4G Data Logger

To get started building your gas sensing applications with SenseCAP, you will need the SenseCAP Sensor Hub 4G Data Logger and a gas sensor of your choosing. The SenseCAP Sensor Hub is compatible with standard MODBUS-RTU RS485 connections, which means that it can be used with most industrial-grade sensors to send collected data to the cloud with ease!

Product Features:

- Simultaneously collect a variety of environmental data

- Supports local storage of data

- Compatible with standard MODBUS-RTU RS485 sensors

- Supports uploading data to any server (SenseCAP Server / User’s private server)

- Support 4G/3G/2G communication, supporting global LTE frequency band

- Built-in GPS positioning function

- Remote upgrade and maintenance capable

- Two power supply options available: DC only, Solar Power (to be purchased separately, coming soon)

- Easy to install and deploy, without requirements of engineering background

- Industry standards, suitable for harsh outdoor environments

Learn more about the SenseCAP Sensor Hub 4G Data Logger on the Seeed Online Store!

SenseCAP SOLO CO2 5000 (A2)

The SenseCAP SOLO CO2 5000 is a digital CO2 concentration sensor that supports RS485 and SDI-12 communication protocols. It is a compact industrial sensor with built in calibration capabilities, which makes it highly suitable for many applications in agriculture, cities, transportation. CO2 levels are an important measurement in almost any industrial context, and the SenseCAP SOLO CO2 5000 is an affordable option to allow you to do just that!

Product Features:

- High performance: high accuracy, fast response, and superior stability

- support MODBUS RS485 and SDI-12

- Compact size, best performance-to-price ratio

- User-friendly: fully-calibrated, easy to install and integrate

- Wide-range Power Supply: 5V ~ 16V

- Wide Range & High Accuracy: 400ppm ~ 5,000 ppm, ± (50ppm+5%*MV)

To learn more, visit the product page on the Seeed Online Store here!

AFM3000-200 Mass Flow Sensor for Gases

Just as detecting amounts of toxic gases in industrial contexts is critical, ventilation performance is equally important. Being able to monitor the flow of air, oxygen and other non-aggressive gases with excellent accuracy, the AFM3000-200 allows you to ensure that confined workspaces are kept well ventilated and safe to work in. In addition, it causes a low-pressure drop in the gas flow across the sensor, which allows it to be used in demanding applications like medical ventilation and respiratory applications.

Product Features:

- Fast update time with excellent accuracy

- Integrated thermal sensor chip with a high-performance 24-bit AD acquisition CMOS microprocessor

- Standard I2C interface for convenient communication with the device

- Ability to measure several gases such as air, oxygen, and other non-aggressive gases

- Special design of sensor channel resulting in a low-pressure drop

- Fully calibrated and temperature compensated out of the box

- The gas flow through the sensor can be bidirectional

- Very suitable for medical applications

To learn more, visit the product page on the Seeed Online Store here!

Grove – Multichannel Gas Sensor v2

If you’re just starting out or simply want to experiment with how gas sensors can improve your IoT application, the Grove Multichannel Gas Sensor is for you. Capable of detecting a variety of gases like carbon monoxide, nitrogen dioxide, ethyl alcohol and volatile organic compounds, the Grove Multichannel Gas Sensors allows you to add gas sensing capabilities to any Grove-enabled device, such as the Wio Terminal or the Seeeduino XIAO and Raspberry Pi with their respective expansion board / Grove base hat!

Product Features:

- Four fully independent sensor elements on one package.

- The ability to detect a variety of gases, besides Carbon monoxide (CO), Nitrogen dioxide (NO2), Ethyl alcohol(C2H5CH), Volatile Organic Compounds (VOC) and etc.

- Qualitative detecting, rather than quantitative.

- Compact size for easy deployment.

To learn more, visit the product page on the Seeed Online Store here!

Pushing the Limits of Gas Sensors with TinyML

Gas sensors simply measure the quantities of different gases in the air, so we can understand the presence of different kinds of gases at any time. Unfortunately, even the same composition of gases in different amounts can indicate different conclusions. But, writing code to cover all these scenarios can be extremely tedious and yet not fully effective.

Fortunately, we can use TinyML, or Tiny Machine Learning. TinyML runs machine learning models on low-power and small microcontroller units to allow cutting-edge data analysis and inference to be performed on the edge! Learn more with this machine learning based alcohol detection project done with the Wio Terminal, the Grove Multichannel Gas Sensor and Edge Impulse by clicking here!

Summary & More Resources

Gas sensors are simple, but truly important and useful in a variety of scenarios. With TinyML, we can push the limits of gas sensors even further to help us deliver more insights from our gas measurement data. If you’re developing an industrial IoT system, be sure to consider the role of gas sensors and how they can help you design more efficient, safer and cleaner industrial processes!

For more resources, you may wish to read the following articles:

- What is Industrial IoT? [Case Studies]

- Edge AI – What is it and What can it do for Edge IoT?

- How the Odyssey X86 Elevates Industrial IoT

- IoT in Smart Agriculture: LPWAN Technologies & Applications