Thermal Imaging And It’s Applications

Background

With the development of new technologies, thermal imaging has come a long way. Thermal Imaging devices were used to be very heavy and not easy to operate before and now it’s possible to have a thermal imaging device as small as the size of your palm! As a result, thermal imaging has become more accessible to everyone!

What is Infrared Radiation?

When talking about thermal imaging, the first thing that comes to mind is infrared radiation (IR). Infrared energy has a wavelength starting at approximately 700 nanometers and extends to approximately 1mm. All objects emit some amount of heat as infrared radiation and this infrared radiation is not visible to us because only “visible light” is visible to the naked eye out of the complete electromagnetic spectrum.

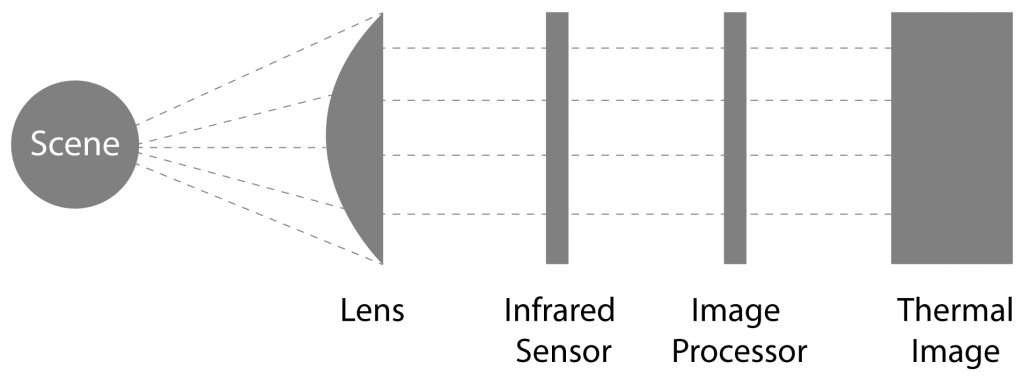

How Thermal Imaging Cameras Work?

A Thermal Imaging Camera has a sensitive heat sensor that can detect tiny differences in temperature from the objects in the surrounding. Then it collects this radiation information from the objects and creates an electronic image known as a thermogram, that is based on the temperature difference information. The hotter an object is, the more infrared radiation it produces. If this intensity is too high, it can be felt as heat.

Now let’s look at how a thermal image camera displays the temperature information in the surrounding.

Normally on a thermogram display, warmer objects are displayed with a yellow-orange hue and this hue gets brighter as the object gets hotter, whereas colder objects are displayed with a blue or purple color.

Where Thermal Imaging Cameras Can be Used?

Thermal Imaging Cameras have a wide variety of applications as follows

- Active Thermography: Non-destructive and contact-free material testing

- Aerial Thermography: Detect people or objects in the field or inspect for geographical properties

- Building Thermography: Building inspections

- Bonding and Sealing: Monitor and control various technical parameters

- High-Speed Thermography: Minute observation of parts and systems and helps in understanding rapid-acting chemical processes

- Electrical Installations Inspections: Inspect electrical installations in high-voltage, dangerous environments

- Inspection of Mechanical Assemblies: Check for irregularities in the heating of mechanical components

- Security Applications: Remote surveillance and border guard of critical infrastructure.

Thermal Imaging Cameras Offered by Seeed

We offer a couple of thermal imaging camera sensors that you can use for your thermal imaging applications. These cameras are very compact, and they can be used in conjunction with a development board in order take the fullest advantages of their capabilities.

Grove – Thermal Imaging Camera – MLX90641 16×12 IR Array with 110° FOV

This IR thermal camera carries a 16×12 array of thermal sensors (MLX90641) and it can detect the temperature of objects from far away with a center area accuracy of ±1℃ and average accuracy of ±1.5℃. In order to obtain the thermal images easily, the I2C protocol is used to get the low-resolution images from the camera. The FOV (Field of View) of this camera is 110°x75°, and the temperature measurement range is -40℃ to 300℃.

This module can be connected to an MCU using the I2C interface. However, it needs an MCU that has over 20000 bytes of RAM to drive the camera. As a matter of fact, Dev boards like Arduino UNO cannot be used with this Sensor camera due to its lower ability of calculation. We recommend you choose Arch Mix as an MCU to control the camera because it really has an excellent performance to process the complex data from the IR sensor camera.

MLX90621 BAB Thermal Imaging Camera / IR Array with ESP32 Module

MLX90621 BAB Thermal Imaging Camera is a non-contact infrared temperature measurement module that integrates the infrared temperature measurement chip by Melexis and features an ESP32 module as the core and is used for short-distance non-contact temperature measurements.

This module is integrated with a dual-core processor, with computing capacity of up to 600dmips, 2MB flash memory, and communication rate of up to 230400bps through UART. The module has its own calibration algorithm, so the user does not need to calibrate before using it. It supports flash encryption and decryption, which can allow the user to store sensitive data, and the user’s storage space is 2MB. The module supports hardware AES acceleration to further protect the user’s data.

Conclusion

We hope you got a clear understanding of thermal imaging cameras and hope to see you all build your next thermal imaging project based on the thermal imaging sensors!