What is a Bill of Materials (BOM) in PCB Design?

We always nag at our customers to upload a BOM list together with their PCB Design to get a quote, whenever they submit an order for the Seeed Fusion PCB assembly service on our online platform. But if it is your first time having a PCB manufactured, you might be scratching your head and wondering what a BOM is.

BOM is the acronym for “Bill of Materials”. It provides a list of all the components needed to build your printed circuit board. Think of it as a parallel to an ingredients list for baking a cake. But instead of a simple listing of flour, eggs and butter scrawled on a random piece of post-it, its resistors, capacitors and chips, together with details to help identify and purchase them, all compiled onto an eloquent spreadsheet. In other words, its a recipe for your PCB design!

It is important to create an accurate BOM, especially if you are handing the job of assembly to an assembly house. If you are missing parts in your BOM, this could lead to an increase in cost and delays due to the need to locate missing parts or alternative sources. And if your BOM does not specify where each part is supposed to be placed on the board, some components can get swapped with something else that isn’t supposed to be there. When that happens, at best, there may be a short delay as your assembler contacts you for confirmation. In a worst-case scenario, you may be receiving boards full of errors that may not be rectifiable.

If you are planning to procure the components on your own and solder them on your PCB by hand, you may be wondering why a BOM is even necessary in the first place, when you can simply list what you need off the top of your head. This is doable if you have a simple PCB design with only a few common parts. However, once you begin designing boards with tens or even hundreds of parts, keeping an organized list of components will become a more reliable strategy than simply keeping a mental note in your head.

What do I include in a BOM?

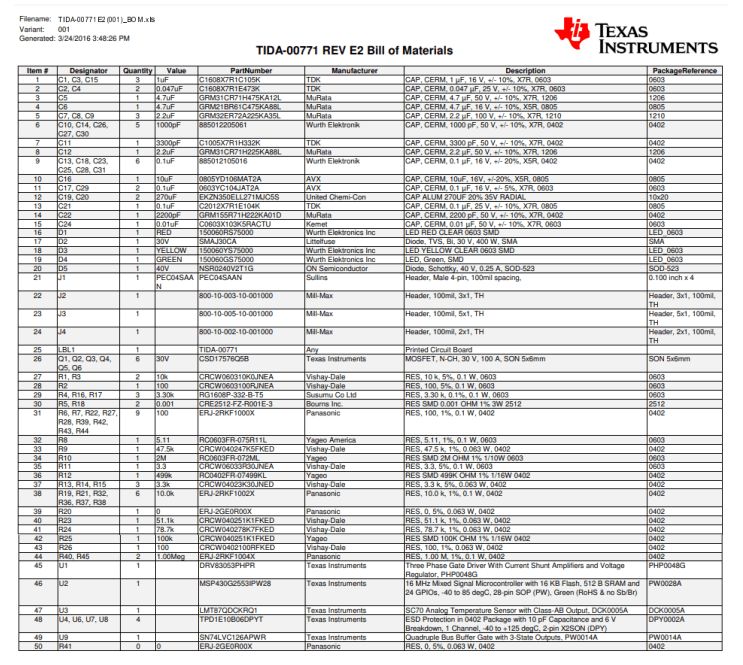

Are you building an electronic product? Chances are, you will be needing a BOM. There are many BOM formats out there catering to different purposes and requirements, depending on what it will ultimately be used for. (If it’s just for your own purposes you can fill as much or as little as you want!) For now, here are some things that are often seen on a typical BOM:

1. Designator (Must have)

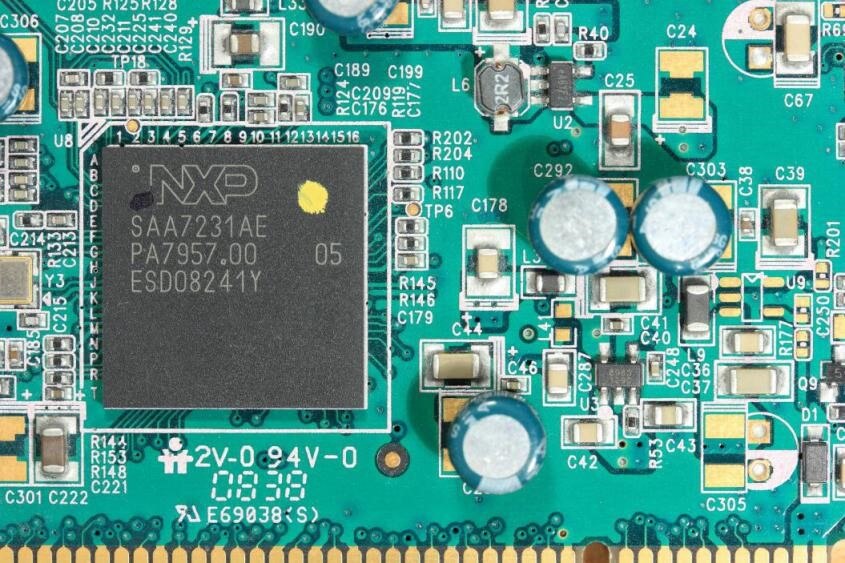

Designators are component labels printed in silkscreen on the board, which tell us where to place the components. For simplicity, standard letters tend to be used for different types of components. For example, resistors are typically labeled R1, R2.., capacitors are labeled C1, C2.., and integrated circuits are labeled U1, U2.., for example. These help you quickly identify the component when it comes to soldering, instead of marking the entire MPN on the boards which takes up valuable PCB real estate.

2. Component Value

Component value means the value specified for certain components. For example, the component value for resistors is resistance, for capacitors, it’s capacitance, for inductors it’s inductance, etc. Having this information will remind you of the value and could help in finding alternative parts during sourcing or help identify parts without the MPN marked on the component package, like a rogue color-banded resistor for example.

3. Manufacturer’s Part Number (Must have)

The MPN is a unique part number given by manufacturers to identify individual products, which is typically a series of numbers and letters. If you have ever gone grocery shopping, chances are that you have pondered on the barcodes and numbers printed on product packaging. These barcodes represent the ‘Product number’, a universal number unique to that product and recognizable by multiple vendors. By providing the MPN, you are telling the vendor the exact part you want.

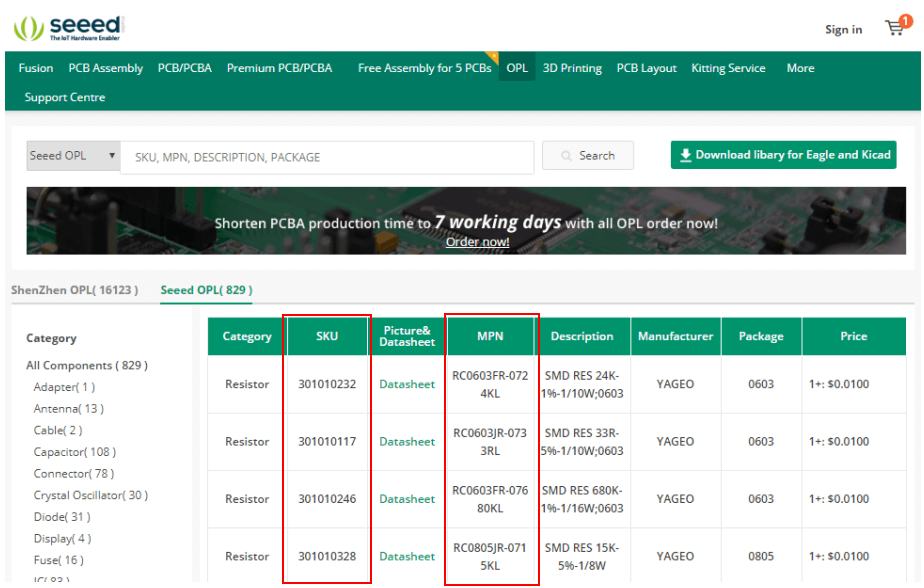

MPNs are not to be confused with SKU numbers, which stand for Stock Keeping Unit. SKU is an identification system used for internal product categorization. A vendor may assign its own internal SKU to a product that has an MPN from its manufacturer. For example, Seeed issues an SKU value to each component in its internal Seeed Open Parts Library (OPL). Likewise, DigiKey and Mouser issue DigiKey and Mouser Part numbers respectively to each component they stock for their own internal use. These should not be confused with MPNs.

4. Quantity (Must have)

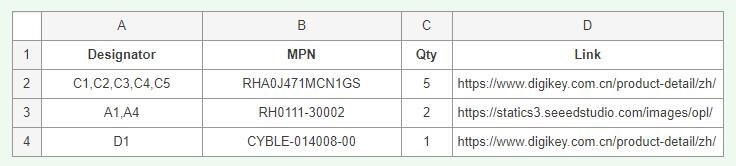

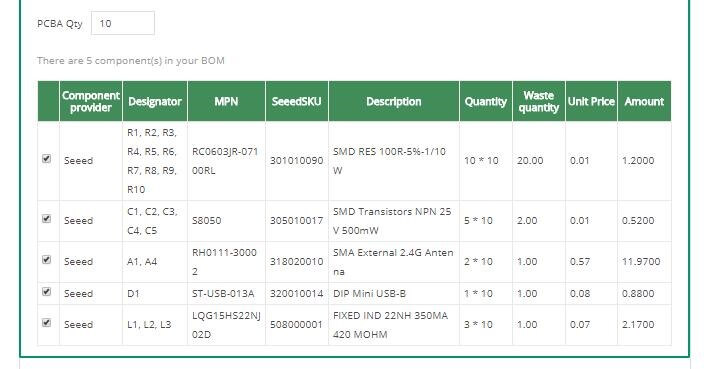

The quantity column specifies how many of a particular component that needs to be ordered, typically per piece. In the BOM for Seeed Fusion PCBA orders, the number will be the quantity of a part on one piece PCBA (whatever was uploaded in the Gerber file section). For example, part number XXXXXX has a total of 5 parts per board, on the locations C1, C2, C3, C4, and C5.

If you upload a panelized design, say 2 x 2, then the BOM quantities should be multiplied by four for the extra copies. Then, if the PCBA quantity entered is 10, this indicates that 10 panels need to be assembled and result in a total of 40 individual pieces once separated from the panel.

5. Description

The description is basically for further information. It is usually not necessary, but if you are handing the BOM over to a purchaser, they may be able to use this information to find alternative parts if the part is out of stock. This will enable your assembly house to save time and get a head start on finding an appropriate substitute for your part. Also, in the case of ambiguous, similar-looking or completely non-existent MPNs, the description can confirm whether you need the cable connector or the header for example.

6. Manufacturer’s Name

This one is a no brainer. As its name suggest, its simply the name of the manufacturer where you are going to get the part from. It is not entirely out of the ordinary for the same MPN to have different manufacturers, so having this may help to avoid the cheaper copy (or tell them you want the cheaper copy). Hence, its a good habit to include the manufacturer’s name and confirm that they are able to provide the part.

7. Package Type

The package refers to the body type that houses the component which is generally standardized for simplicity. Whether it’s 0603, 0805 for SMT passives or SOT-123 or QFPs for semiconductor parts, the package gives a general idea of the size and shape of the part, and it can also be helpful when you are laying out the PCB, as you’ll know what kind of footprint to use.

The package column is optional for the assembly house. But it is still a good idea to include them in your BOM as it may assist operators when programming and operating the Pick-and-Place machine.

8. Placement Method

This section is to remind yourself or to tell your manufacturer, how you want your part to be assembled on your board. This can be as simple as just saying top and bottom, the value of which can be easily underestimated. (This information may be so important that it deserves its own column in the BOM file.) Placement method can be through-hole, surface mount (SMD), or a combination of through-hole and SMD.

9. Part link

This one is easy. It’s simply a web link that leads to more details about the part, to you, or whoever hunting down the parts’ reference.

10. Alternate Part number

Part stock is ever-changing. While a part may be in stock during the time your BOM was created, it might not remain in stock by the time your manufacturer begins procurement. An alternate part number provides a substitute part in case your original part is out of stock and saves time that would otherwise be spent sending emails back and forth.

What kind of BOM is required by Seeed?

Already think that BOMs are complicated? Fortunately, BOMs required by Seeed for its Fusion PCB assembly service are very very simple! It only requires 3 elements out of all that we have discussed, as Seeed’s intelligent online quoting system will be able to help extract the other information.

They are the Designator, MPN, Quantity, and the Part link (optional).

If you are getting your PCBs assembled by Seeed and are using parts from the Seeed OPL, then you can also choose to enter the Seeed SKU value instead of the MPN. For example, both the part number CC0402JRNPO9BN330 or the Seeed SKU number 302010000 can be entered in Seeed’s BOM template.

Where can I get good quality components?

Building a BOM starts with suppliers. In the old days, this meant amassing hefty component catalogs and sifting through the pages for each part. But now, it’s just a case of Googling or Binging the MPN and clicking the first link, which will probably be one of the following suppliers on our list.

Remember, Seeed can take out the hassle of parts procurement on your behalf. Through Seeed’s Fusion PCB Assembly (PCBA) service, Seeed can source them from reputable suppliers such as DigiKey and Mouser. Here are some reputable distributors that have been supplying Seeed with quality components all these years!

1. Digi-key

Seeed’s collaboration with Digi-Key began back in 2015. They are North America’s fourth-largest electronic component distributor, and the fifth largest in the world. Despite this, they are probably the most popular and well known due to their expansive online catalog that caters to a broad market.

Digi-Key’s support has been integral in Seeed’s efforts to provide turnkey PCB assembly services and will continue to be, as Seeed continually seeks to review and improve its products and services to provide the maker community with more exciting offerings.

2. Mouser Electronics

Mouser is also a leading semiconductor and electronics components distributor in the US and one of the world’s largest. They regularly offer new products and technologies for design engineers and buyers, with extensive product offerings for semiconductors, interconnects, passives, and electromechanical components. Working together with Mouser has enabled Seeed to provide our customers with a ton of great components to create new and interesting projects.

3. Element14

Previously Farnell Electronics, element14 (or Newark element14) is named after Silicon, the 14th element in the periodic table. Element14 is a distributor of products for electronics system design, maintenance and repair, which specialize in offering unique development boards and evaluation kits.

4. Particle

Launched in 2013 on Kickstarter, Particle is an IoT platform that simplifies the building of IoT products, to enable businesses to conveniently build and deploy IoT solutions for solving real problems. Through its platform, Particle adds connectivity to products and provides security and device management. Seeed has teamed up with Particle so that our customers can also have access to more great products available in the IoT industry. Particle has supplied Seeed with the P0 and P1 Wi-Fi modules, which are available in the Seeed Open Parts Library (OPL). Never heard of the Seeed OPL? Read on!

BONUS: The Seeed & Shenzhen Open Parts Library (OPL)

Specially created to complement the Seeed Fusion turnkey PCB assembly service, the Seeed OPL is a selection of in-stock parts that are cheaper and ready to go. By selecting components from the Seeed OPL, customers can drastically reduce their PCBA production time from 20 working days to just 7.

But the 800+ components in the Seeed OPL have proven to be too narrow a selection for some of Seeed Fusion’s customers. Hence, the Shenzhen OPL was introduced last December. Boasting over 15,000 parts, our customers can now choose from an even wider selection. Unlike the Seeed OPL, which shares Seeed’s own stock of components, the Shenzhen OPL reaches out to local suppliers right on our doorstep – which so happens to be the Silicon Valley of hardware. As a result of Seeed’s advantageous position in Shenzhen, the manufacturing hub of the world, we partnered up with HuaQiang, from the famous electronics marketplace in HuaQiangBei, to integrate their stock directly into our PCBA service. This way, our customers can enjoy faster production times and reduced costs. For more details on the Seeed OPL and Shenzhen OPL, head over to our Fusion FAQ.

Now that you have a basic understanding of how to make a BOM and how the components come about, try your hand at making a BOM for a PCB design and sending it to a fab house. Instead of soldering on the components on your own, remember that the Seeed Fusion PCBA service can do it for you. Simply visit our online order platform, upload your completed BOM and PCB Gerber files, and you are good to go. To find out more about the steps to make a Seeed Fusion PCBA order, navigate to our guide here.

Now, Seeed Fusion is also offering batch production with no operation fees for orders of 100 pieces or more. Simply upload the files and the discount will be automatically applied.

We look forward to working with you!