What can laser cutting do? Everything you need to know about laser cutting!

As the name may suggest, this is the process of cutting a material using a laser beam. This can be done to trim down a material or to help cut it into complex shapes that more conventional drills would struggle with. Apart from cutting, laser cutters can also raster or etch designs onto work pieces by heating up the surface of the workpiece, thus boring off the top layer of the material to change it its appearance where the raster operation was performed.

Laser cutters are handy tools when it comes prototyping and manufacturing; they are used by hardware companies/start-ups/makerspaces to create cheap, quick prototypes, and they are tools used by makers and hardware enthusiast as a digital fabrication ‘weapon’ to bring their digital designs in to the physical world.

How do Laser Cutters Work?

There are several different types of laser cutters, but essentially use the same process of using a beam of laser to cut material. The system sends out a beam of intense light though reflects though an array of mirrors to the cutting head. And within the cutting head, the laser is focused through a lens and narrowed down to an extremely concentrated beam. The bean is then projected down at the material and used to cut down material.

The difference between different types of laser cutters comes form what types of lasers the machines have. The type of laser defines what type and thickness of material it can cut through, because different laser types have different power ranges.

What is a Laser Cutter?

A laser cutter is a type of CNC (Computer Numerical Controlled) machine, meaning that it’s controlled by a computer. A maker can design their ideas on the digital software and send it to the laser cutter to be cut. Once the laser cutter received the file, the machine uses a laser beam to cut into or etch into the material on the cutting bed. Laser cutters are a good all around tool because they can be used to make different style of design. Common laser cutters are primarily used to cut materials like wood, acrylic, cardboard, paper and etc.

For this, we’ve launch an affordable desktop laser cutter on our Seeed’s Bazaar allowing you to create what you want/need. If you would like to buy your own desktop 3D printers, don’t miss out here!

Our Desktop laser cutter on Seeed’s Bazaar

Types of laser cutting

There are main types of laser cutters: CO2 lasers, fiber lasers, and neodymium lasers. Although the laser cutters are all built very similarly, they are distinct in that each type of laser has a specific power range, thus each can be used to cut though different materials and thicknesses.

CO2 Lasers: The laser is generated from electrically stimulated gas mixtures(mostly Carbon Dioxide). CO2 lasers are the most common types of laser cutters because they are low power, relatively inexpensive and efficient, and can be used to cut though various types of materials

Material: wood, Cardboard, leather, acrylic, glass, some other plastic and forms.

Neodymium Lasers: The laser is formed from neodymium doped crystals. Theses laser have a high higher intensity, and therefore cut through much thicker materials.

Material: metal, plastics and ceramics.

What can you do with laser cutting?

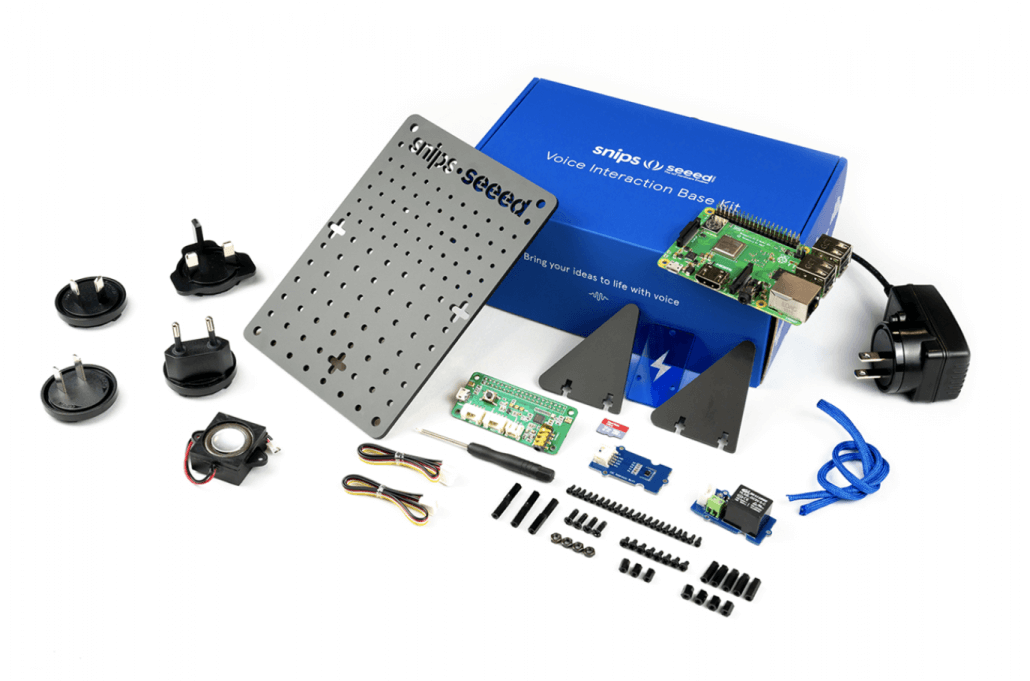

Laser cutting can produce some impressive projects. It can be used in various industries, from mechanical engineering and more technical to decorative. A great example is that our product – Snips Voice Interaction Base Kit, has a laser-cutted acrylic in it, where it demonstrates perfectly how useful it can be. Laser cutting also usually combine with other digital fabrication technology such as 3D printing to allow us to have ultimate design freedom and achieve results.

But for now, let these laser cutters change your production and start exploring the joy of digital fabrication!