Types of Relay – Which One Should You Use?

A relay is an electrically operated switch, the relay opens when the two contacts are disconnected, and the relay turns on when the two contacts touch. They are designed to be controlled with low voltages like 3.3V like the ESP32, ESP8266 etc or 5V like your Arduino to change the state of an electric circuit from one state to another.

They often used to isolate low voltage circuits from a high voltage circuit to control high voltage devices.

If you interested in how to do that with an Arduino and find out more about the Relay, you can check our Arduino Tutorial on How to Control High Voltage Devices with Relay Modules.

But with thousands of relay in the market that are compatible with different platforms for different purposes, there are just so many different types of relays. So how do you pick a relay for your project?

No worries as after this guide, you will learn about:

- Different Types of Relays

- How they work

- Advantages and Disadvantages

- Special Functions Relay

And pick the relay that best suits your project! Without further ado, let us jump right into the first type relay

Types of Relays

Depending on the operating principle and structural features, relays are categorized into different types mainly:

- Electromechanical Relay

- Solid State Relay

- Reed Relay

There are still various other types of relays but their use are either limited, too costly or not widely available and thus, we are not going to include them in this guide.

Without further ado, let us look at the 3 most common relays being used currently with the first being:

Electromechanical Relay

These relays are constructed with electrical, mechanical and magnetic components. They are made with a coil that induces a magnetic field when energized. This magnetic field attracts the armature (a movable contact) which closes or opens the contacts.

When the coil is de-energized, the coil loses its magnetic field and a spring then retracts the armature to its normal position which then again, opens or closes the contacts.

Here is an example of an Electromechanical Relay in action to power a motor:

Electromechanical Relays are designed for AC or DC source depending on the applications. The AC and DC relays work on the same principle as electromagnetic induction but its structure may differ in its coil construction. The DC coil has a freewheeling diode to de-energize while AC relays uses laminated cores to prevent current losses.

The Electromechanical Relays are further split into 2 types:

- Latching

- Latching Relays has either one or two coils that can remain in the last position when the current is turned off. Even after the input voltage is interrupted, this relay maintains its set or reset condition until it receives the next inverting input. It is also called a keep relay.

- They are useful in applications where low power consumption is needed as they do not require any current to maintain their position.

- Non Latching

- On the other hand, a Non-Latching has a spring or magnet that maintains its initial state of NC (Normally closed) when no current is flowing through and maintains its state only while being actuated. When current flows through the coil, contact is opened.

Electromechanical Relays are then further classified by their switching type according to the number of terminals:

- Single Throw (ST)

- eg. SPST (Single Pole Single Throw) – Simplest Relay which works like a button. The relay is normally open and when a current flows through, the relay closes.

- Double Throw (DT)

- eg. SPDT (Single Pole Double Throw) – Has one common terminal and 2 contacts which are great for selecting between two options.

Advantages and Disadvantages of Electromechanical Relay

Advantages

- Able to withstand large inrush currents

- High mechanical structure reliability, not susceptible to external electromagnetic environment

- Cheap and cost-effective

- Able to carry high voltage, high current load

Disadvantages

- Electromechanical relays are slower than other types of relays at 5 to 15ms

- Larger package sizes, not suitable for small projects

- Electromechanical relays tend to have a shorter life than other types of relays due to mechanical wear

Solid State Relays

Also known as SSR, Solid-state relays are basically a circuit with various electronic components that has the same function as the previous Electromechanical relay. They use solid-state components to perform the switching operation without any moving parts.

SSR switches on or off when a small external voltage is applied across its control terminals. They use semiconductor devices to switch the conduction and disconnection of high voltage loads.

A typical SSR consists of a LED driver and a photosensitive MOSFET. When the current is flowing through, it lights up the LED where when the photosensitive MOSFET detects it, it triggers the gate of TRIAC (Triode for alternating current) or SCR (Silicon Controlled Rectifier) that switches the load and the high voltage circuit will be turned on.

Advantages and Disadvantages of Solid State Relay

Advantages

- Fast switching speed, the switching time is dependent on the time required to power the LED on and off—approximately 1 ms and 0.5 ms. For instance, the G3MC202p serial SSR we use is ½ of load power source cycle +1 ms.

- Totally silent operation, almost no noise

- No physical contacts mean no sparking, allows it to be used in explosive environments.

- Increased lifetime, even if it is activated many times, with no moving parts and contacts, carbon would not be build up.

- Compact, thin-profile SSR of monoblock construction with an all-in-one lead frame incorporates a PCB, terminals and heat sink, which is much smaller than mechanical relays and can integrate more channels.

- Not susceptible to physical shock

Disadvantages

- Contact resistance is relatively large, usually above 100 ohms, which will generate more heat, so it needs to be used with a fan.

- High cost

Reed Relays

Reed relays consist of a switch with magnetic strips (also known as reed) sealed within a glass tube filled with inert gas (to protect from corrosion) which moves under the influence of an external magnetic or the induced field from its solenoid. The magnetic field applied to the coil is wrapped around the tube that makes the Reed move so that the switch can happen without requiring an armature to move them.

As you can see above, there is no axial magnetic field generated when no voltage is applied to the coil where the reed blade will be disconnected because of the rigidity. When a voltage to the coil is applied, a transverse magnetic field will be generated and the reed will be magnetized. One contact turns N pole and the other turns S pole where they will be connected.

Do note that when using a Reed Relay with an inductive load (such as load that comes from a motor), you need to add a protection circuit between the relay and the load.

Advantages and Disadvantages of Reed Relay

Advantages

- Low power consumption, small size

- Because it is sealed in an inert gas, very little affected by environmental factors such as temperature and humidity allowing it to have high environmental adaptability

- Switching speed is fast, about 10 times higher than an electromechanical relay

Disadvantages

- Low load voltage and low current

- Susceptible to inductive loads

Special Functions Relay

Other than the mentioned types of relay, here at Seeed, we also offer a few other types of relays that have special functions that I feel you will like:

Heelight Relay

Want to control a relay with sound commands? This Heelight Relay does exactly that!

Heelight Relay is uniquely designed to control a relay using digital sound commands over a distance of about 10 meters. It is built with the Heelight Core (https://longan-labs.cc/heelight-core/), a smart sound sensor that can recognize up to 500+ digital sound commands.

Simply, you can now turn on and off lamps, fans, solenoids, and other small appliances that run on up to 220VAC or DC power by playing a sound with your smartphone, computer, or any audio player. The Heelight Relay is integrated with an STM32 Arm Cortex microcontroller, pre-programmed for digital sound recognition during the manufacturing of this module hence doesn’t require any further programming to process the digital sound commands.

The module can be configured to respond to a digital sound command using the two built-in momentary push buttons.

Codec-Adaptive Wireless Relay

Want to control high voltage devices wirelessly? Check out this wireless relay! ‘

This wireless relay is a codec-adaptive RF receiver with a single channel relay. It helps easily deployment of wireless AC control for electrical appliances. It features:

- Max 30 difference codec, unlimited controller or transmitter of each codec

- Adaption of most popular RF remote controller, except rolling code

With a wireless function, they are perfect for your projects like home automation, security, industrial control and many more!

Summary

Now that you’ve known how each type of relay works and its advantages and disadvantages, you now know which relay to use in your projects? Get a relay here now today!

Still do not know which relay fits your project?

No worries as we have summarized Seeed’s existing relay modules, all are compatible with Arduino and Raspberry Pi, to offer an overall guide to our users.

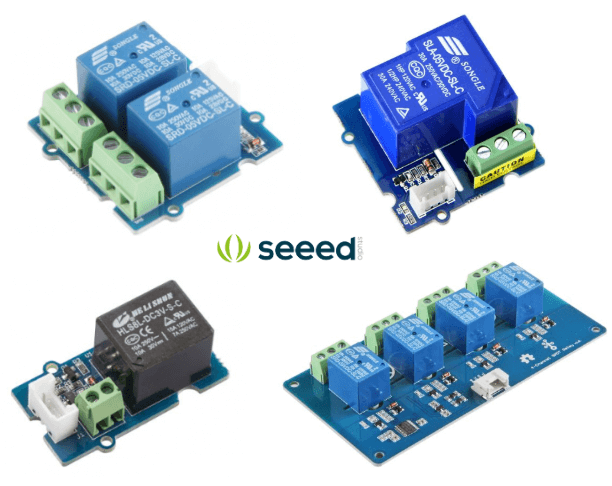

Currently, We have 11 relay modules available in Seeed Bazaar, 5 being Electromechanical relays, 5 Solid-state relay, 1 is reed relay.

This guide features a comparison between all of our relays to help you pick a relay that fits your project needs. It is a very useful guide for those who want to use a relay with Arduino and Raspberry Pi. Check out the new guide here.