Inside Made in China: One-Stop Factory HI-tour service

Hello community fellas, and welcome back to our Inside Made in China series. For those of you who are new to this series, it is all about how things are “Made in China”. We’re curating series posts to tour you around online to local factories in Dongguan, where sits our new maker space Chaihuo x.factory Dongguan. We regard it as an interface for the global maker community to the local manufacturing system, with the aim to open up the local manufacturing resources to the community, lower the manufacturing barrier and help you to gain a better understanding of the manufacturing ecosystem.

Ever since our last offline factory tour with Mitch Altman and his HTTC group (Recap), we already have some seeekers interested in participating one and so now we are pleased to announce our brand new service – Factory Hardware Innovation Tour (HI Tour) to who wants to visit factories and gain insights into China’s manufacturing ecosystem. During the tour, each factory will invite their professionals to host each visit and to answer questions that you may have.

→Factory HI-Tour Service←

This factory HI (Hardware Innovation) tour is a customised service provided by Chaihuo x.factory Dongguan and so if you have any factory visiting inquiries or you want to get a residency membership at x.factory Dongguan (Click here), Please email us at [email protected].

→Standard Factory HI Tour Route←

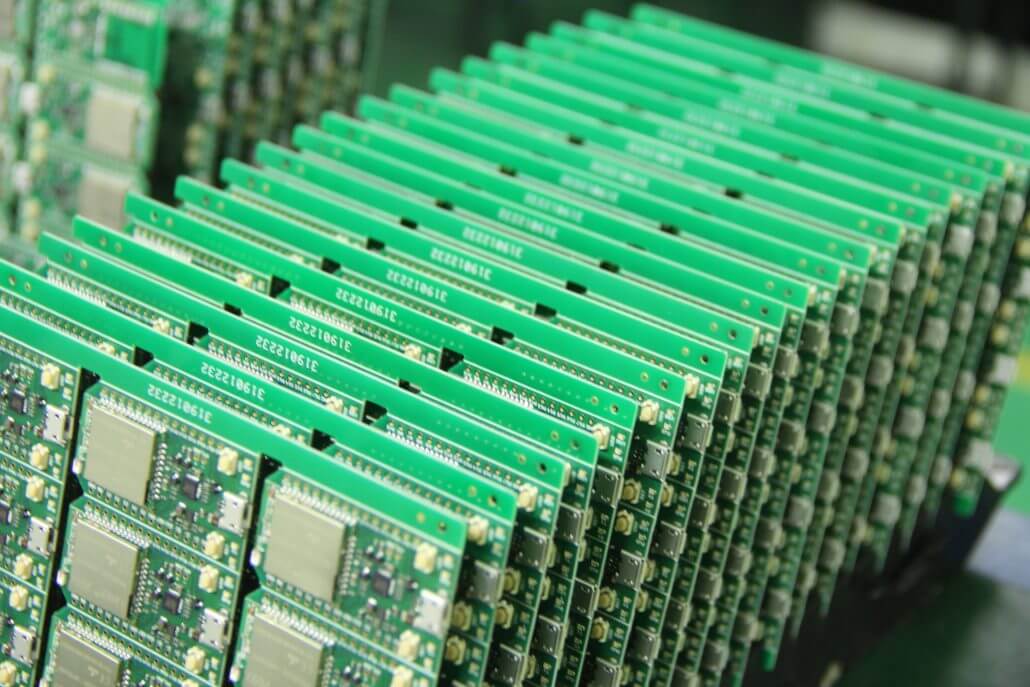

1. PCB Factory

PCB manufacturing has always been one of the largest market demands in the technology industry, so we arranged a PCB manufacturing factory as the first stop of this high tour to bring makers one step closer to the backend. By visiting the PCB factory, you will able to get a real close look at the manufacturing process of PCBs such as Board Cutting, Drilling, Panel Plating, Dry Filming, Etching, AOI, Brown Oxide, Lay-up, Lamination and other necessary manufacturing flow. This enables start-ups to become familiar with production and supply chain management.

2. CNC Factory

CNC machining and manufacturing is also no stranger to the hardware start-ups. For that, we have arranged a representative of precision parts manufacturing, mainly focusing on industrial grade CNC prototyping. During the tour, you will be able to witness industrial manufacturing process from CAD Drawing Review, Material Preparation, Mold Processing, Trial Production, First Article Inspection, Mass production, Self Check, Secondary Operation, Secondary Operation Inspection, Rework to the Final Warehousing, allowing us to understand each step of the manufacturing flow.

3. Woodworking Factory

Woodworking is one of the most common techniques for us and can be applied to projects of almost any field and so became one of the stop of this high tour. By visiting the factory, high tour participants can have a deeper understanding of the manufacturing process of the Commercial wooden projects and learn about specific processes such as Material Selection, Material Cutting, Longitudinal sawing, precision cutting, CNC Machining, Hand Crafting, Surface Treatment and etc.

→Substitute Options←

If the above itinerary does not meet your needs, you can substitute with the following options. Also, you’re welcome to let us know your specific needs and we could tailor a tour for you.

- Laser Processing Factory

Laser processing can be used in industrial applications such as metal processing, sheet metal fittings, and chassis enclosures. Its advantages are that it can be used to produce very complex parts and the parts do not require further processing, resulting in greatly reduced production time and cost,. Therefore, through a laser processing factory visit, you will be able to learn different types of laser processing techniques such as Laser Cutting, Laser Welding, Laser Drilling, etc. and get familiar with such techniques and apply to individual projects.

- PCBA Factory

For start-ups, the PCB manufacturing process may not be enough, so we can also arrange a visit ago a manufacturer that focuses on PCBA manufacturing including a combination of SMT processing and DIP processing. Through our visit, you can gain knowledge about PCBA process including carrier board, Solder printing, patching, reflow soldering, plug-in, wave soldering, test, and quality inspection.

Just can’t wait to visit some of the factories and get insights of Made in China? Please contact us at [email protected] to know more details about our HI Tour.