Inside Made in China: Woodworking Factory Tour

Ever wondered how things are ‘Made in China’? Chaihuo x.factory Dongguan aims to open up the local manufacturing resources to the global maker community, lower the manufacturing barrier and help you to gain a better understanding of the local manufacturing ecosystem. For that, we thought it might be a good idea to start with exploring and sharing some of the ‘factory secrets’ with you aperiodically via online factory tours. And this leads to this new column Inside Made in China, where we will tour you around to our manufacturing partners’ factories online!

Final assembling of products

Initial wood processing

As a kickoff, we would like to present you a quick factory view to a woodworking factory JinYuan based in Dongguan, which is also one of our friends for years! A huge thank you to Zhou, the owner of JinYuan, for opening up to share their expertise exclusively with our community.

It is not a large factory, but it is fully-equipped with tools and machines required for woodworking. Touring in the factory, you will see the entire manufacturing process of products, from cutting rough edges to engraving parts, surface finishing to the final assembling. There’re roughly 5 sections divided by the woodworking process, including Material Storage section, CNC machining section, Parts Cutting & Engraving section, Surface finishing section, and Assembling section.

Using CNC to drill set holes

Woodworking, as it implies, making things out of wood, which is one of the most common making techniques, where it can be used for projects across almost any field. Here at JinYuan, there are three main focuses:

- Customized wooden decorations for commercial space

- Customized doors/windows/structure for architecture

- Prototype design for makers/STEAM products

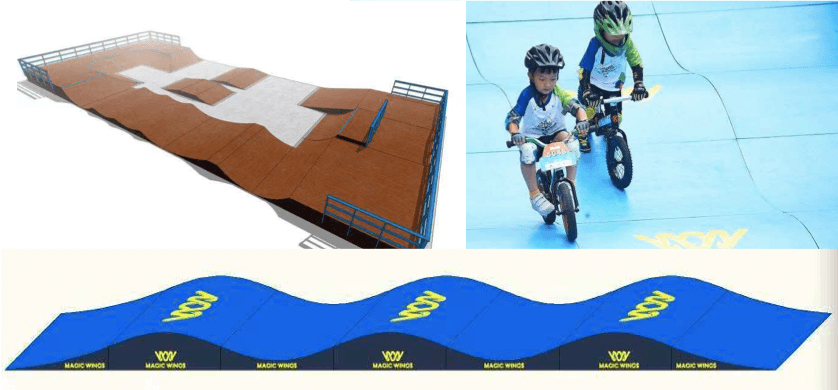

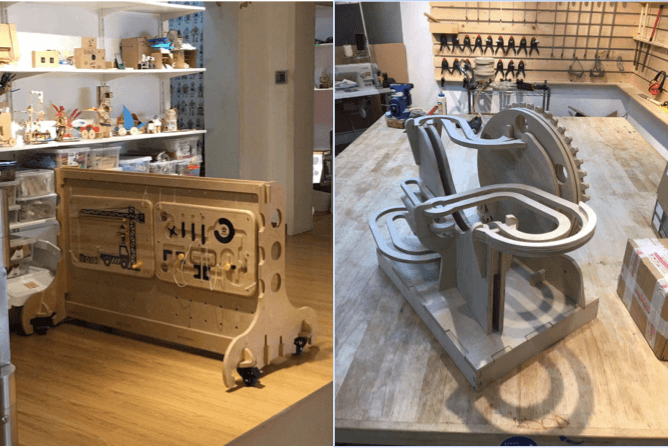

Here are some of the works that they customized for their customers:

- Wooden ramp tracks for BMX

- Customised Wooden Car Frame

- STEAM products

- Wooden tracks for workshop

While factory earning profit for their employees is the name of the game, it is also important to show customers that how things are made. We’ll keep exploring to more factories around and soon we’ll have offline factory high tour service available for makers who would like to visit various types of factories, and use x.factory as a router to connect with the local manufacturing ecosystem. If you have any inputs or suggestions for both our online and offline tours, welcome to hint us in the comments.

Engraving wooden parts manually

Partly finished components laying aside

Engraved corners for indoor decorations

Currently, we’re still working on preparing our Chaihuo x.factory Dongguan for an official opening in early December, and member applications will be available later this month. So if you are a maker who wants to access to x.factory’s resources, whether it’s the equipment, co-working space, manufacturing resources, etc., please feel free to contact us at anson.he@chaihuo.org.