PCB Etching Technique and Analysis of Etching Solution

With the development of the PCB industry, the impedance requirements of various wires have become higher and higher, which inevitably requires stricter control of the width of the wires. In industrial production, the quality of PCB is getting better and better, and the reliability is getting higher and higher; but the design process is becoming more and more diversified and more perfect. The use of etching technology in PCB processing and assembly is becoming more and more widespread.

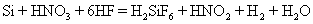

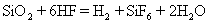

Wet etching of silicon dioxide is usually hydrofluoric acid, reaction is as follows:

Wet etching of silicon dioxide is usually hydrofluoric acid, reaction is as follows:

Practical application is to use diluted hydrofluoric acid or added fluoride used as a buffering agent to control the etch rate. Silicon nitride can be heated to 180 ° c phosphoric acid solution (85%) for etching. Wet etching of aluminum or aluminum alloy is the use of phosphoric acid, nitric acid, acetic acid and water mixture, typical for 80% phosphoric acid, 5% nitric acid, acetic acid and 10% water. By nitric acid oxidation of aluminum to aluminum, and then will be dissolving alumina phosphate removal, and so forth to achieve the effect of circuit board etching.

Practical application is to use diluted hydrofluoric acid or added fluoride used as a buffering agent to control the etch rate. Silicon nitride can be heated to 180 ° c phosphoric acid solution (85%) for etching. Wet etching of aluminum or aluminum alloy is the use of phosphoric acid, nitric acid, acetic acid and water mixture, typical for 80% phosphoric acid, 5% nitric acid, acetic acid and 10% water. By nitric acid oxidation of aluminum to aluminum, and then will be dissolving alumina phosphate removal, and so forth to achieve the effect of circuit board etching.

What is etching technique

The etching technique is a technique for selectively etching or stripping the surface of the semiconductor substrate or the surface covering film in accordance with the mask pattern or design requirements in the semiconductor process. Etching techniques can be divided into wet etching and dry etching, chemical solution used in wet etching through chemical reactions in order to achieve the purpose of etching, dry etching is usually a plasma etching, its effect may be the impact chips by plasma surface physics, or possibly a plasma activated chemical reaction between base and surface atoms, or even role may be a composite of the two.Wet etching

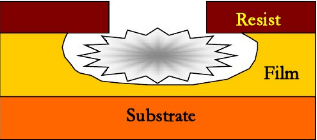

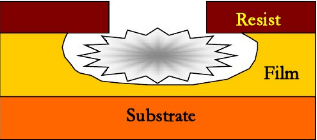

Wet etching is a technique in which etching materials are immersed in an etching solution for etching. It is the most common etching method. There are three factors that affect the etching rate of the etched object: etching solution concentration, etching solution temperature, and stirring. Qualitatively speaking, increasing the etching temperature and adding stirring can effectively increase the etching rate; The characteristic of wet etching is isotropic.

- Wafer Etching

- PCB Etching

Advantages of wet etching

- Good surface uniformity.

- Good adaptability, suitable for almost all metals, glass, plastics, etc.

- Low cost.

- With excellent selectivity, the current film will stop after etching without damaging the film of other materials below.

Disadvantages of wet etching

- Isotropic etching;

- The fidelity of pattern etching is not ideal;

- The smallest line of the etched pattern is difficult to control;

Dry etching

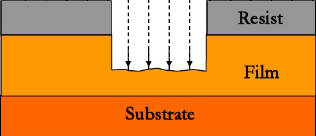

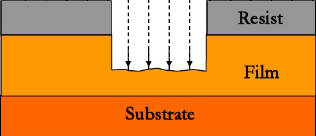

Dry etching is a technique that uses plasma to etch thin films, and is the most important method for etching devices in sub-micron sizes.It uses plasma to react with the surface film to form volatile substances, or directly bombard the surface of the film to be bombarded; The characteristic of dry etching is anisotropy.

Characteristics of dry physical etching

- Etching mechanism: Physical ion sputtering;

- Etching rate: fast;

- Line width control: easy to control;

- Side wall profile: Anisotropy;

Characteristics of dry chemical etching

- Etching mechanism: Active element chemical reaction;

- Etching rate: slow;

- Line width control: Not easy to control;

- Side wall profile: Isotropic;

Advantages of dry etching

- Anisotropy of etching profile;

- Minimal photoresist shedding;

- Good etching uniformity;

- Low cost of chemicals;

Disadvantages of dry etching

- The choice of etching for the underlying material is relatively poor;

- Plasma induced damage;

- Expensive equipment;